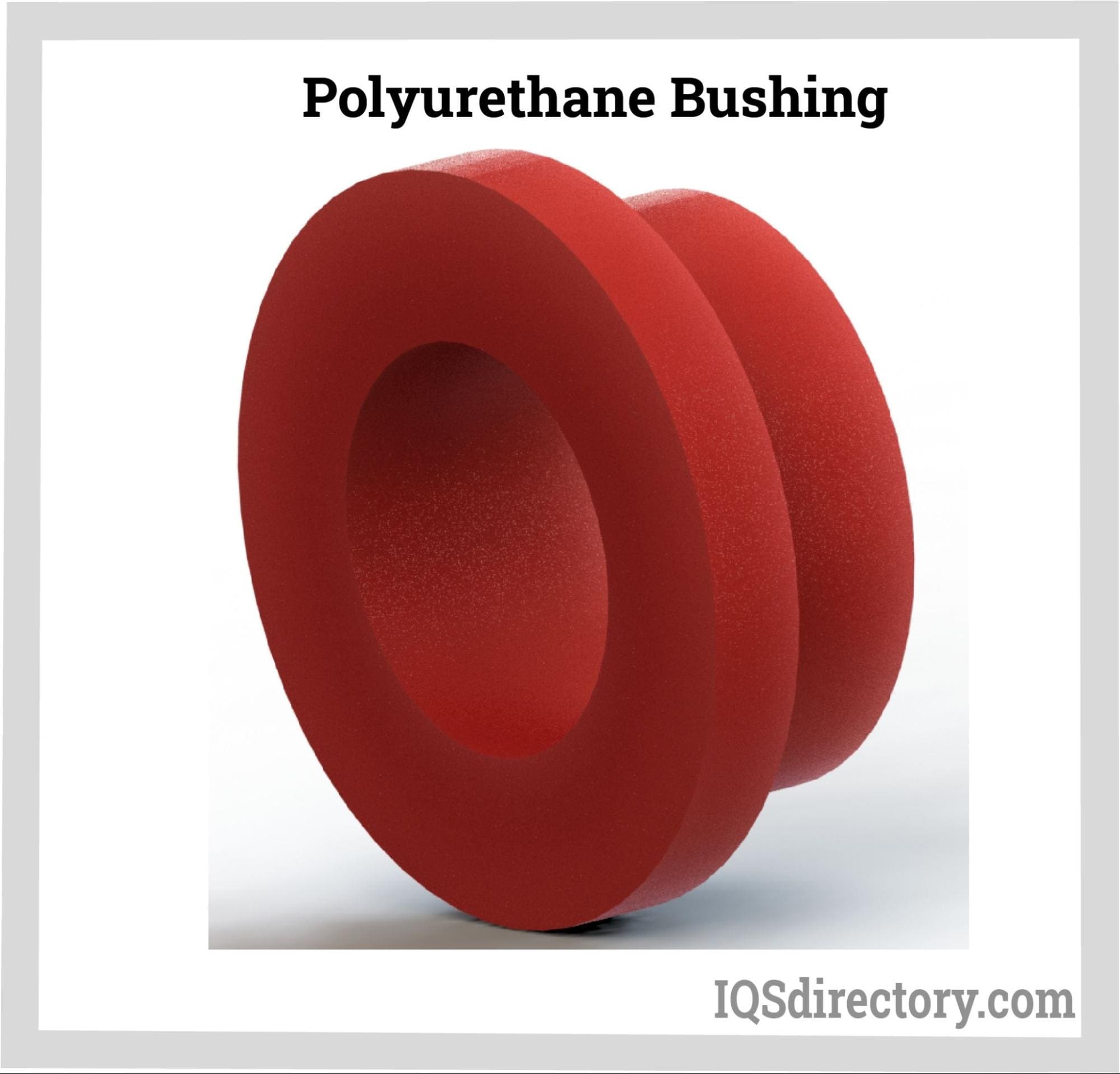

A urethane ring has a specialized use as an independent plain bearing known as a urethane bushing. Bushings don’t have any rolling components like most conventional bearings do. Instead, as the energy is deflected through the bushing, they serve as a protective contact between two parts and dampen the energy communicated between them. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

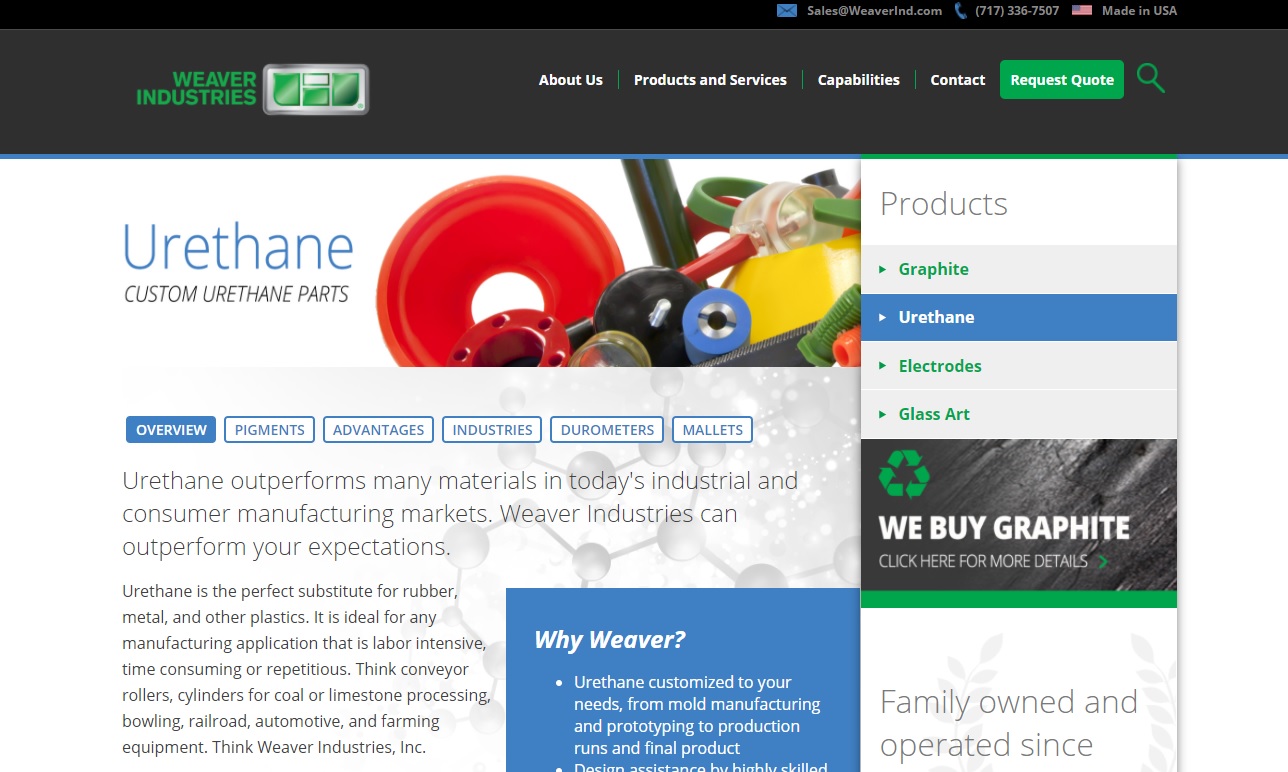

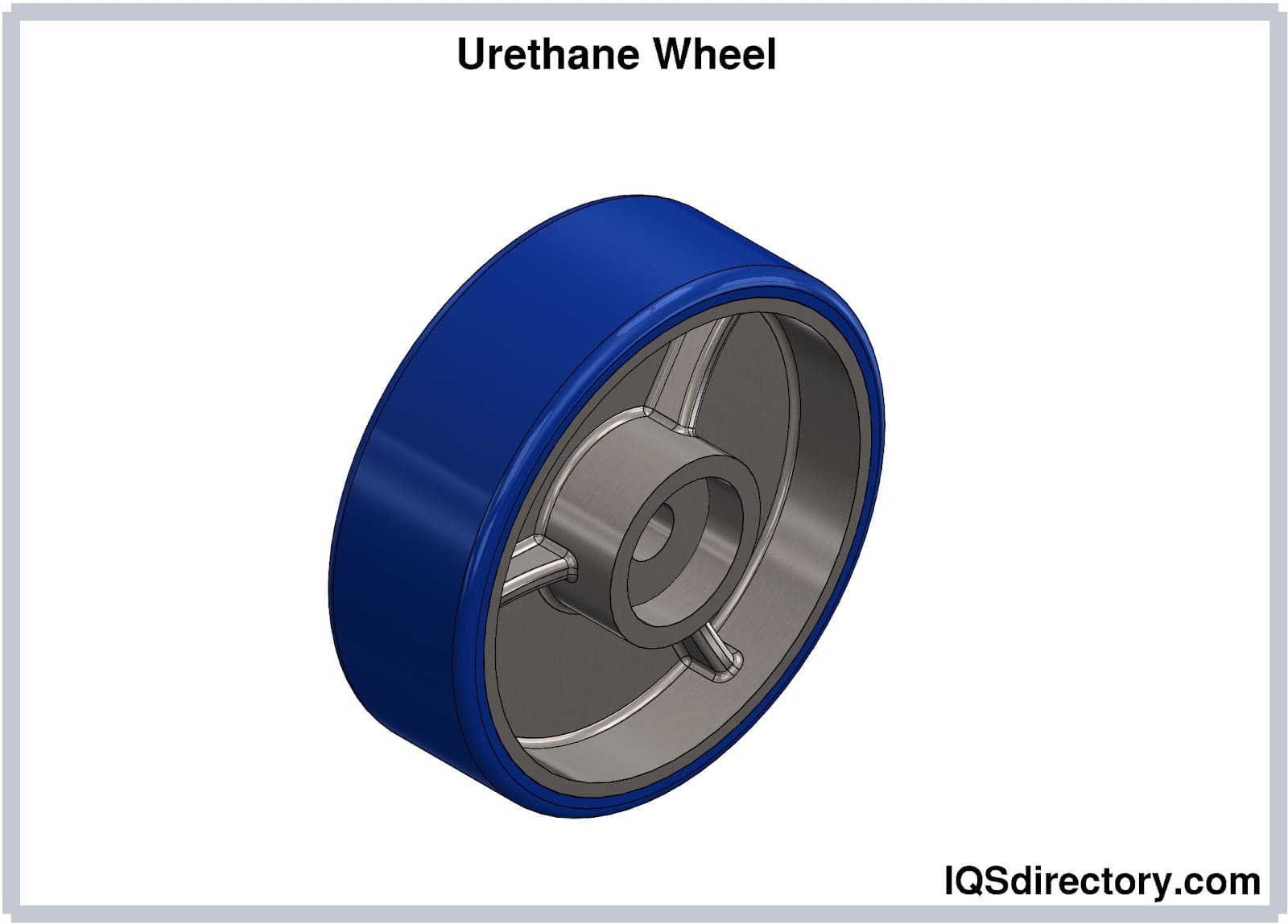

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

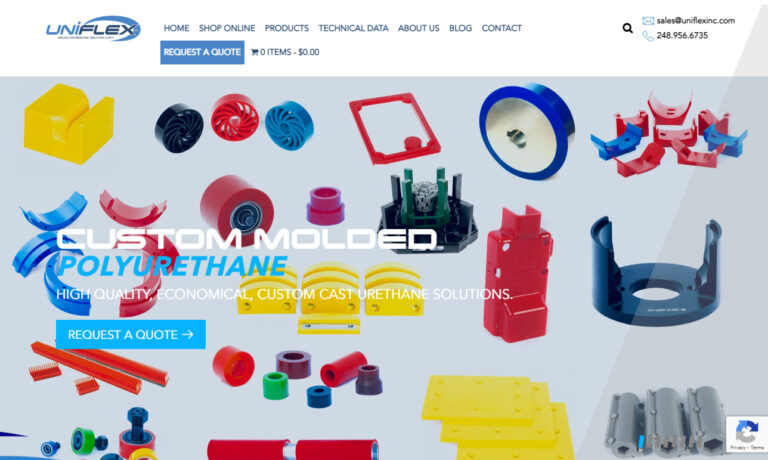

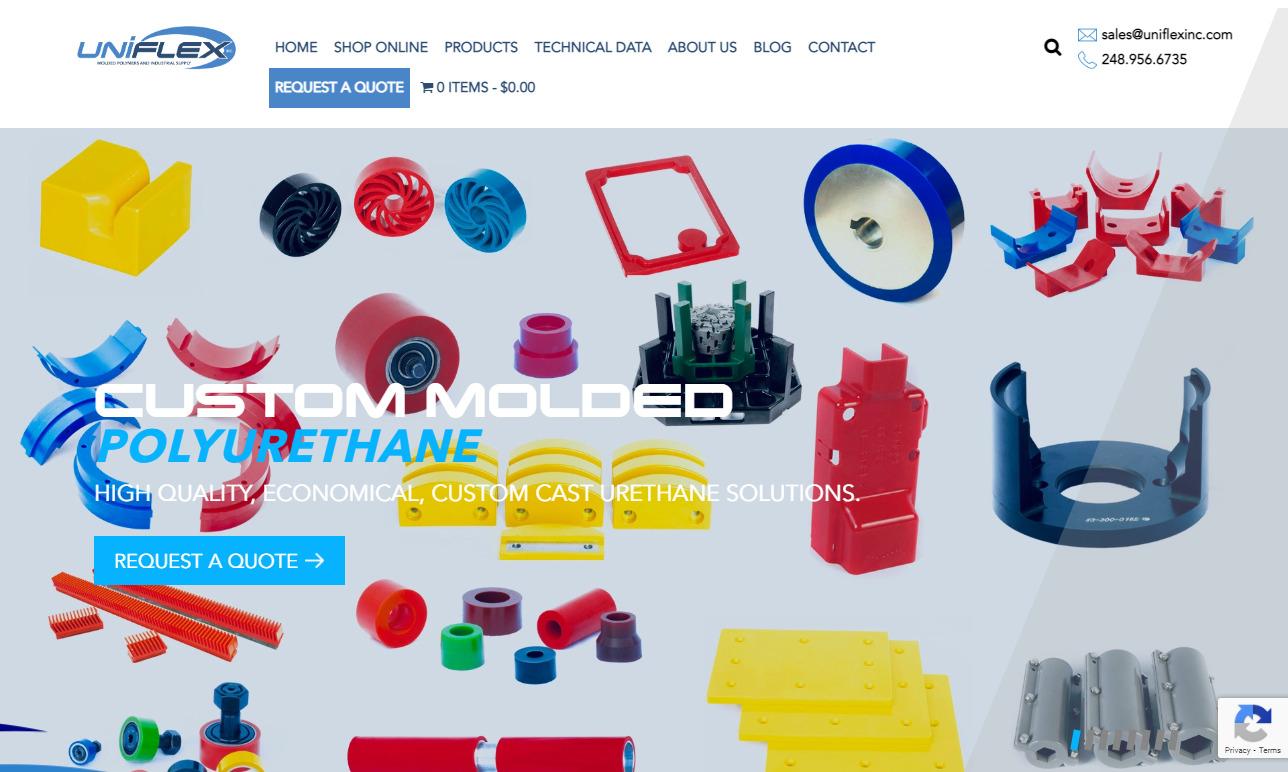

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

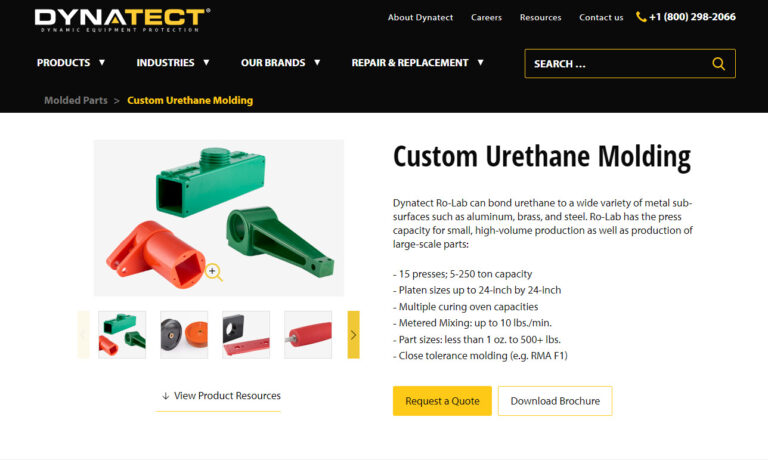

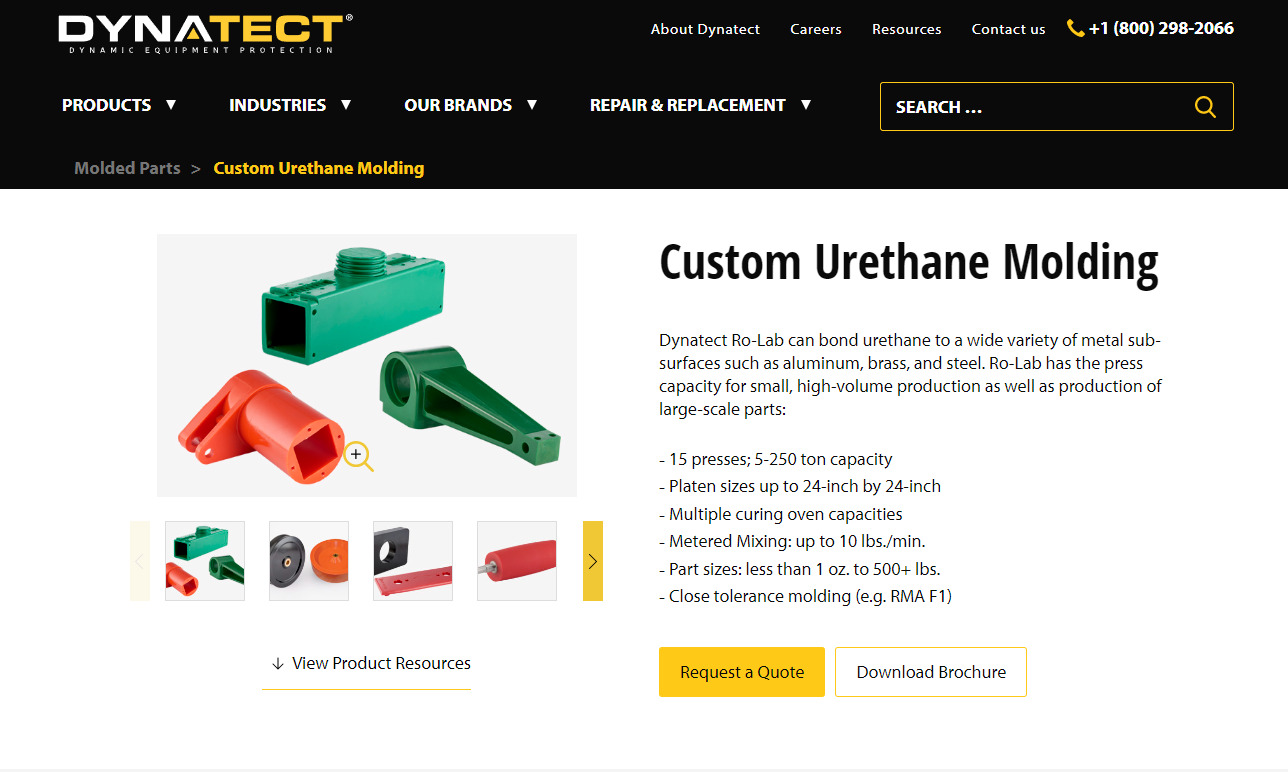

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is...

More Urethane Bushing Companies

Urethane bushings are a class of bearings used in the manufacture of automobiles as shock absorbers to preserve suspension and alignment parts. Urethane bushings, also referred to as urethane bushes, are a typical simple bearing. Urethane bushings are made of polyurethane, an elastomeric plastic resin containing urethane and organic compounds.

Bushing Designs

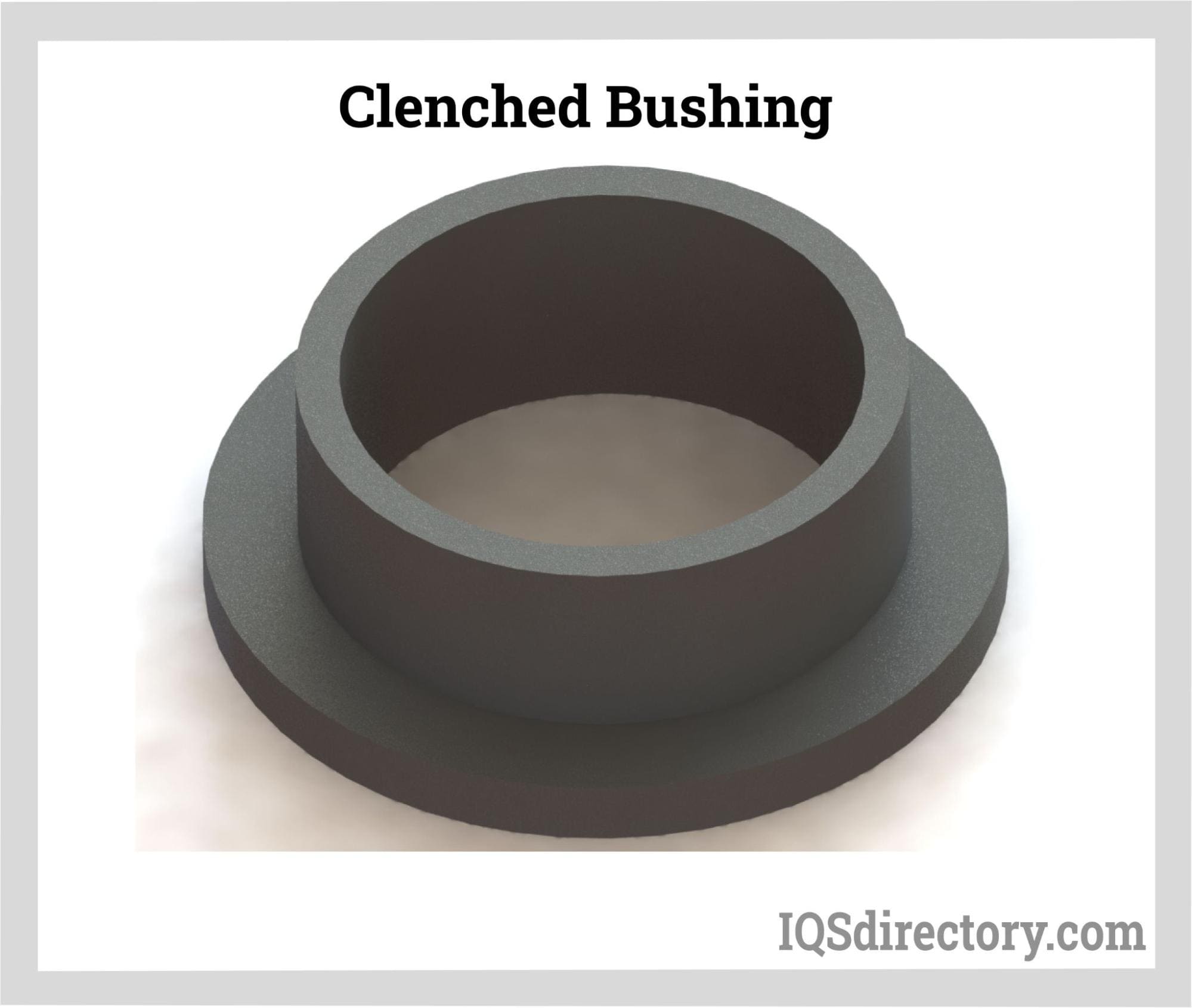

Urethane bushings can be made in various typical designs, such as solid (sleeve and flanged), split, and clenched.

Split Bushing

A split bushing has a slit along its length and can allow some shaft size changes without needing to be changed or retooled; therefore, it does not require a precisely matching bore component.

Solid Bushing

A solid bushing may have a flange or a sleeve. This bushing is solid all around and has a seamless, smooth surface.

Clenched Bushing

A clenched bushing has a clench (tight grip) across the cut, similar to a split bushing.

Urethane Bushing Manufacture

High-performance polymers make urethane bushings, and friction-reducing additives are frequently included. They are produced using a technique known as reaction injection molding (RIM). RIM involves injecting a polyisocyanate component and polyurethane resin into a mold, which reacts and then dries to produce bushings with various strengths, textures, and colors. For optimum performance, each urethane bushing must be separately installed during installation.

Advantages of Urethane Bushings

Compared to rubber or metal bushings, urethane bushings operate better due to their many advantageous features. Higher durability, increased density, and a lower likelihood of caster and camber change are just a few of the many benefits. Other benefits of urethane bushings include their remarkable strength, heat, cold, and friction resistance, greater responsiveness, improved control of suspension movement, and strong resistance to cold flow.

In demanding applications, polyurethane bushings typically last longer than rubber bushings because of their superior wear resistance. They can be a better option for usage in high-performance vehicles or severe settings because they are also more resistant to temperature extremes.

Hardness

The biggest disadvantage of poly bushings is also one of their advantages: hardness. The OE rubber bushings on most automobiles range in durometer from 50 to 60A. The range of polyurethane bushings is 75 to 95A, depending on the supplier and location. This rating means that poly will not deflect or bend as much as your original bushings, improving alignment holding and stability for your suspension parts and increasing NVH (noise, vibration, harshness) resistance.

Mechanical Bonding

While some areas are different, employing a through-bolt allows poly bushings to "float" rather than being fixed in the housing like OE rubber. As a result, poly bushings permit more rotation instead of internal resistance, resulting in a flexure suspension and constant alignment of control arms or leaf springs, as opposed to the bushing itself torquing and wearing itself down.

Low, or No, Maintenance?

Since polyurethane bushings function best when oiled to reduce the likelihood of squeaking, be most effective, and lengthen their lifespan, maintenance is necessary. The good news is that they shouldn't require maintenance for roughly five years if they are lubricated during installation. Even some manufacturers claim that the only time their bushings require lubrication is during installation.

Durability

In addition to having a high wear resistance, polyurethane can tolerate factors that would destroy OE rubber, such as motor chemicals, road salts, coastal conditions (salt), ozone, etc. Additionally, polyurethane's durability is especially advantageous for heavy-duty or extreme-condition vehicles to offer several performance benefits for automobiles.

Applications for Urethane Bushings

Urethane bushings are trusted to enable movement and offer stability in various situations, from consumer uses to urethane suspension bushings for commercial heavy-duty trucking and transportation applications. They are chosen depending on several variables, including the velocity of the application and the applied load, formula, size, and durometer.

Heavy-duty trucks, commercial machinery, and car suspension systems frequently use urethane bushings. Urethane bushings are specifically made for the production of automobiles because they last longer and control movement better than alternatives like rubber but are less harsh on car parts than metal. They are primarily designed to reduce friction and wear or constrict and retain the motion of mechanical parts.

Although urethane bushings are most frequently used in the automotive industry, they are also used in other applications, such as agriculture, industrial manufacturing, and construction. For example, they are used to suspend automation equipment and material handling machinery like conveyor systems, as well as in farming machinery like combines and tractors. Typical applications comprise torque arms, control arms, hydraulic presses, automation equipment, material handling solutions, bump stops, body mounts, hydraulic motors and pumps, and trailing arms.

Choosing the Proper Urethane Bushing Manufacturer

To make sure you have the most productive outcome when purchasing urethane bushings from a urethane bushing company, it is important to compare at least 4 to 5 manufacturers using our urethane bushing directory. Each manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each urethane bushing company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple urethane bushing companies with the same message.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

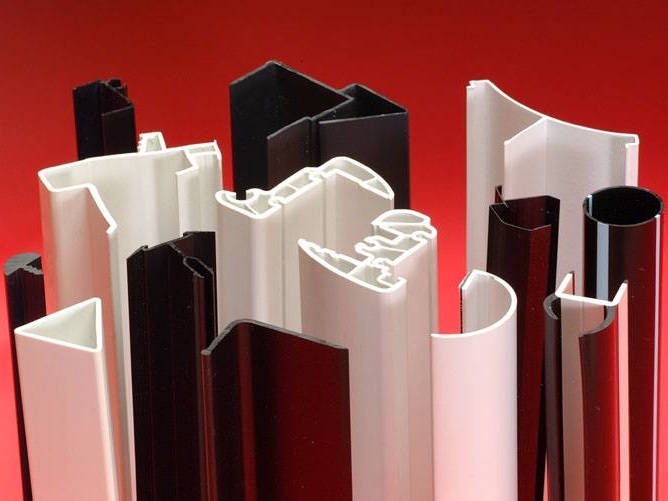

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

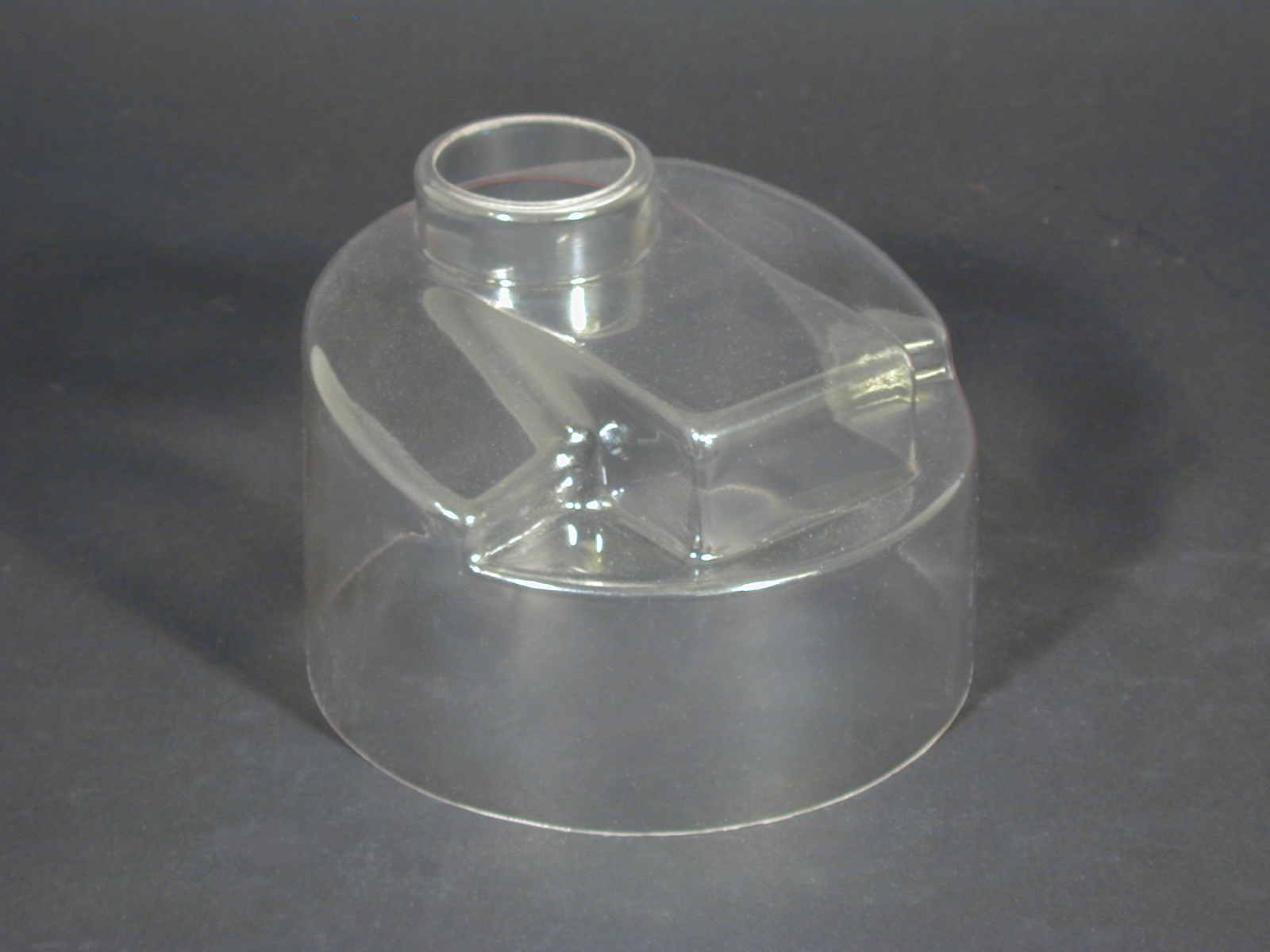

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services