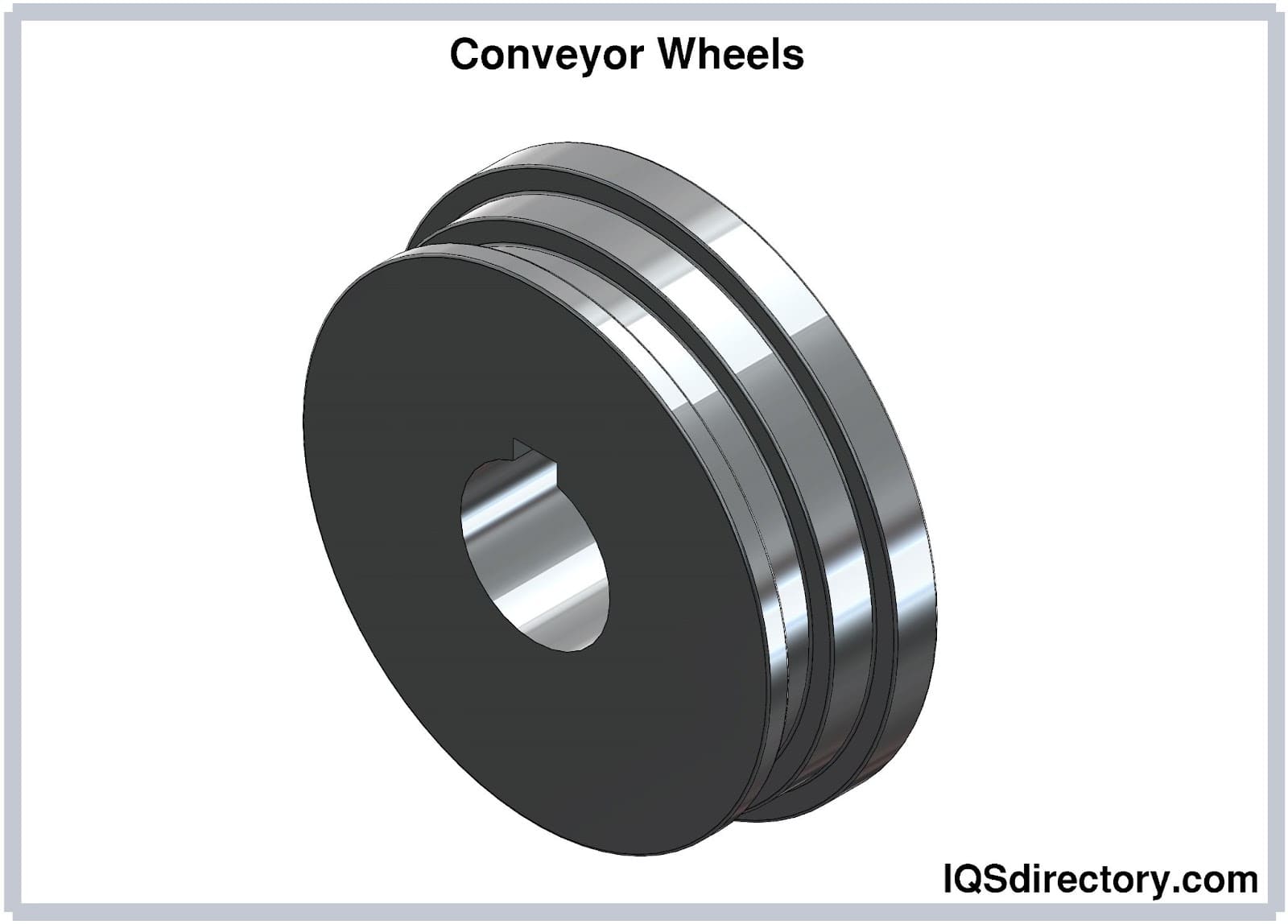

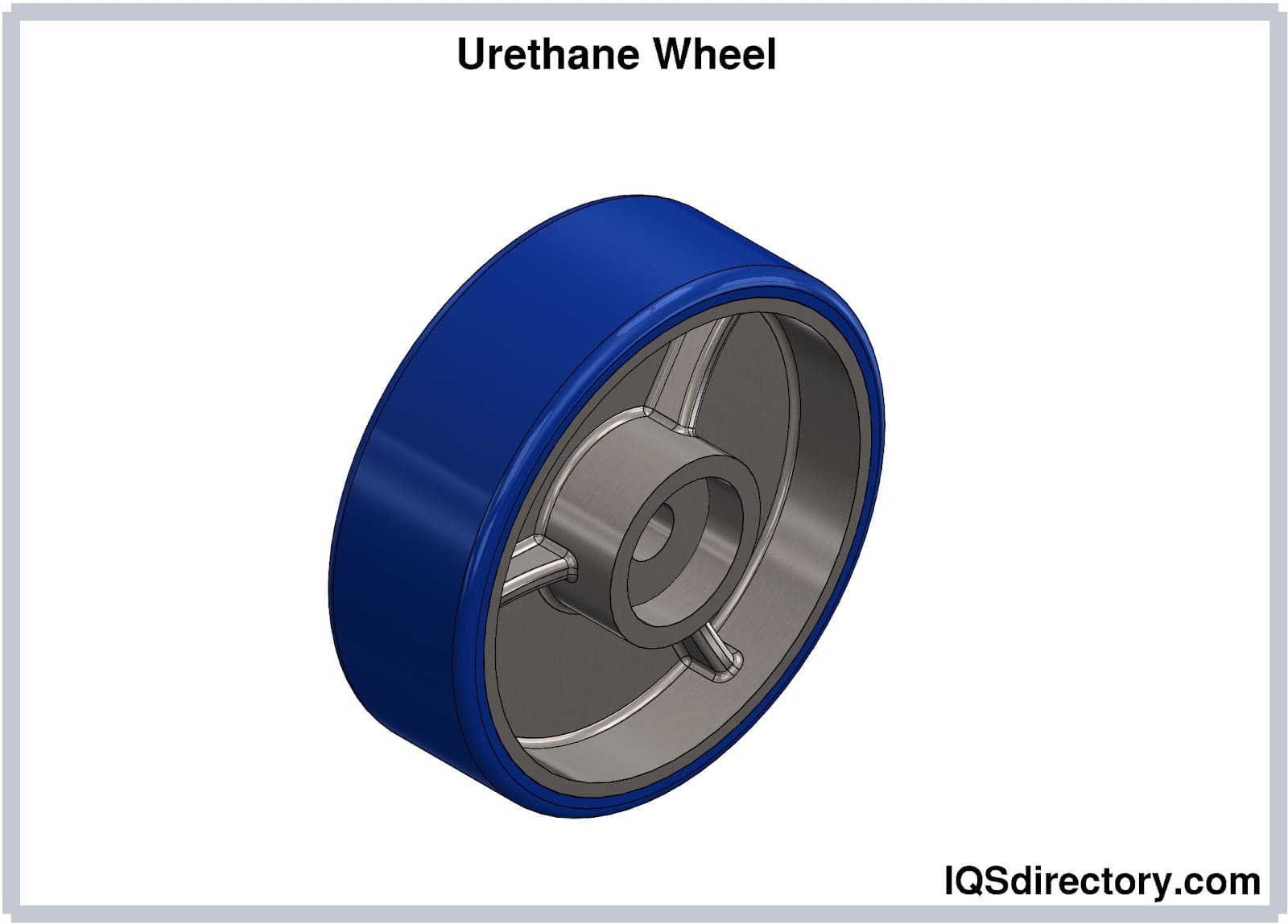

Conveyor wheels are a series of supported wheels in a frame over which goods are transported manually or flow by the principle of gravity. Conveyor wheels can be utilized for creating simple gravity roller conveyors. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

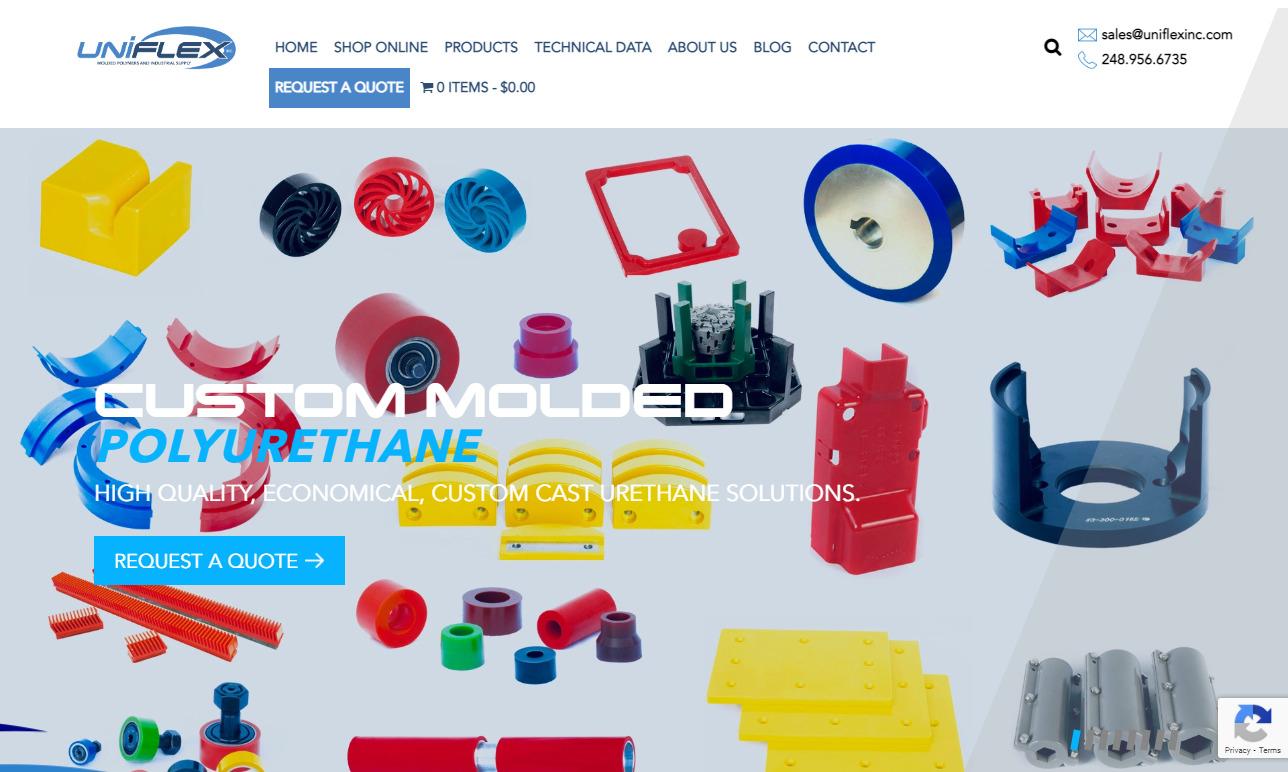

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

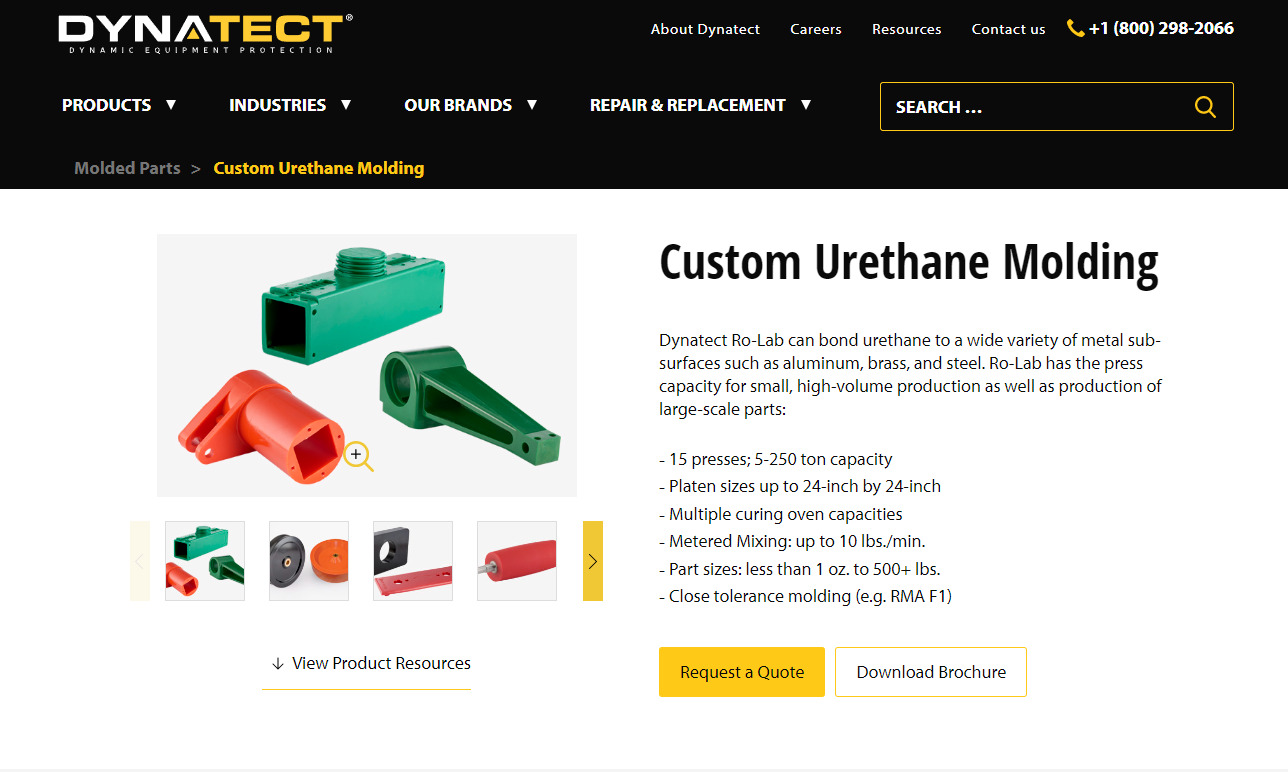

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is...

More Conveyor Wheel Companies

What are Conveyor Wheels?

They can also be used for side guides in applications that involve material handling. They are a very fast, easy, and affordable way of getting products moving. These wheels are designed for revolutions up to one million at full load.

Types of Conveyor Wheels

The different types of conveyor wheels include:

Skate Wheels

These conveyor wheels are an efficient and economical solution for handling materials. They are designed for the transportation of packages along rapid and flexible conveyors. They are typically utilized on gravity conveyors. They are very good for moving goods from one point to another quickly.

The wheels spin on a bearing, making the transportation of packages on a conveyor almost effortless. Skate wheels for conveyors can be made from different materials. Different types of skate wheels based on the material used to make them are given below:

Plastic Skate Wheels

These types of conveyor wheels are very strong and made in many different styles. Some have a hollow core, making them lightweight. These are used to distribute the weight of a load evenly.

Other plastic wheels are steel threaded. These steel threaded wheels are designed to be used in push-back racks where the skids are pushed up and down the incline conveyor. These wheels are mounted on the conveyor by bolting them, and they do not ride on an axle.

The last style is a built-in spacer conveyor wheel, which increases spacing due to its built-in spacer.

Acetal Wheels

Acetal conveyor wheels are resistant to abrasion.

Polycarbonate wheels

Polycarbonate conveyor wheels exhibit high capacities and good resistance to impact.

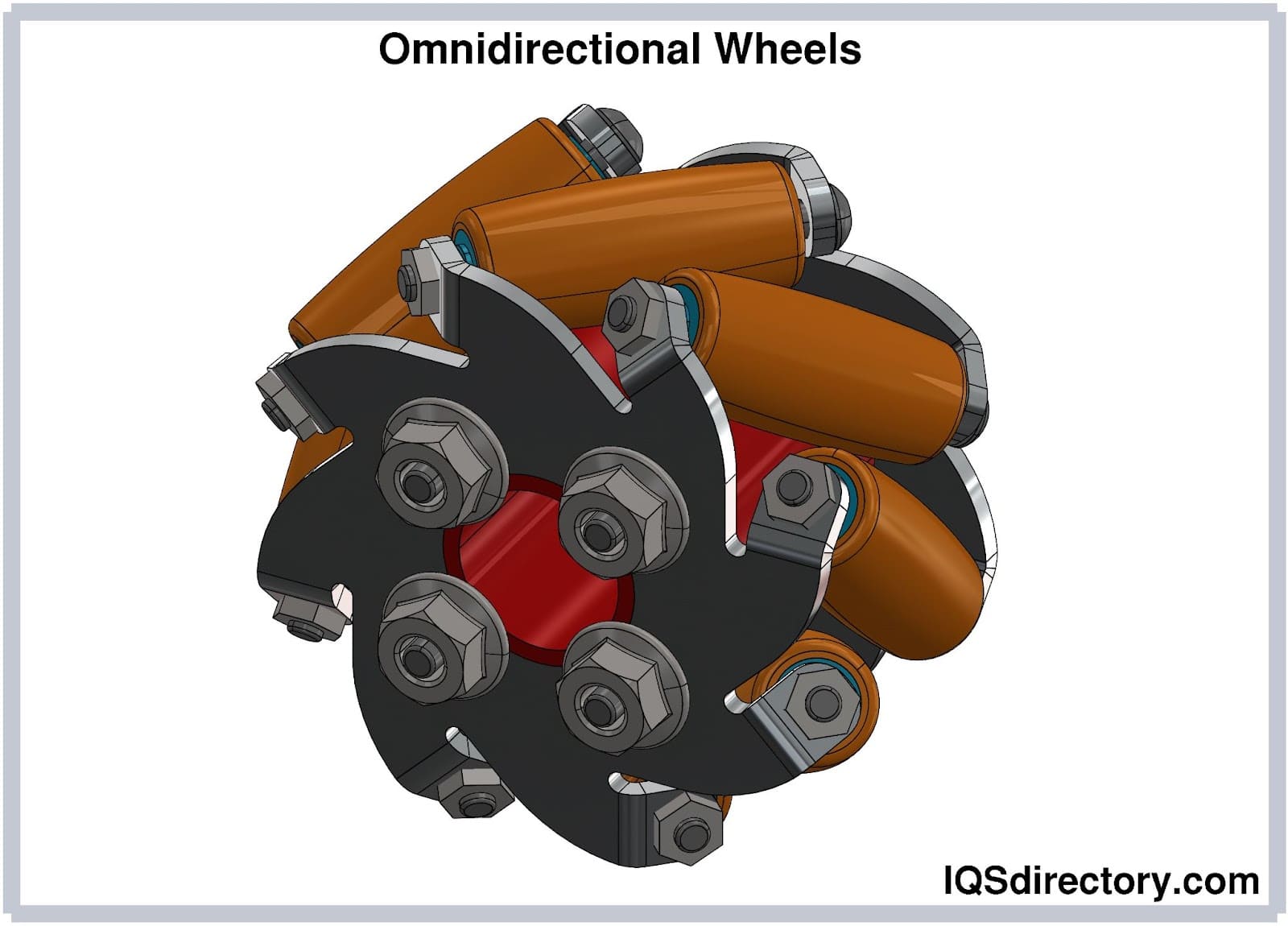

Omnidirectional Wheels

Omnidirectional conveyor wheels are designed in such a way that they can handle or rotate in any direction. They achieve this with a sufficiently rigid, smooth, and flat surface. These wheels are employed mostly in the junctions and switches sections of gravity conveyors, in transfer working, and in machines.

In the assembly, the wheels rotate on the main spindle. The assembly consists of a series of barrels in offset, each assembled into a spindle made of stainless steel. The assembly guarantees continuous support of the surface of the load. Omnidirectional wheels exhibit good corrosion and abrasion-resistant properties. They run very smoothly, and they are versatile and easy to install.

Series OW 570-580

These types of wheels are very versatile since they allow modular assembly. They can also be motorized for automatic installations for those types having hexagonal holes. Half of the number of wheels that support the package should be considered when evaluating the allowable loads. This is because after assembling, the small barrels are presented offset by them.

Omnidirectional Wheels OW 500

These types of wheels are rugged, smooth, and compact. They can be used for diameter 120, medium-heavy loads, and loading and unloading vehicle systems.

Applications and Benefits of Conveyor Wheels

The applications and benefits of conveyor wheels include:

Applications of Conveyor Wheels

- Vehicle loading and loading systems

- Gravity roller conveyors

- Warehouses

- Docks

- Backrooms

- Skate wheel conveyors

Benefits of Conveyor Wheels

- They are light in weight and have a compact design, allowing hassle-free installation as an independent unit or into existing conveyor rail systems.

- Omni wheels require low maintenance and are resistant to wear.

- Omni wheels can rotate at any angle and therefore are capable of handling packages in different directions.

- With omnidirectional wheels mounted on a conveyor, complex manipulations of packages can be handled on a minimal footprint.

- Conveyor wheels are impact resistant and wear-resistant.

- They are capable of handling a wide range of loads.

- In terms of functionality with omnidirectional wheels, combinations of movements can be achieved by combining multiple modules.

- Omnidirectional wheels eliminate complex actuation associated with swivels, pop-ups, and pneumatics.

- Conveyor wheels made from polycarbonate exhibit high capacities and good resistance to impact.

- Conveyor wheels made from acetal are resistant to abrasion.

Choosing the Correct Conveyor Wheel Manufacturer

To make sure you have the most productive outcome when purchasing conveyor wheels from a conveyor wheel manufacturer, it is important to compare at least 4 or 5 manufacturers using our list of conveyor wheel companies. Each conveyor wheel manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each conveyor wheel company website using our patented website previewer to get an idea of what each business specializes in, and the use our simple RFQ form to contact multiple conveyor wheel businesses with the same quote.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

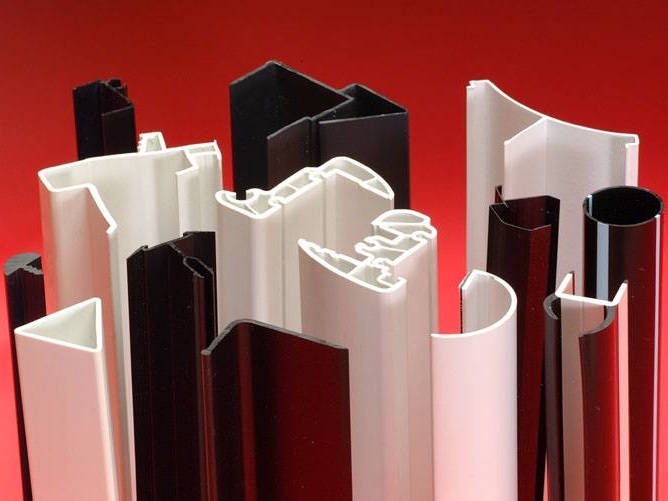

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services