From foam insulation in home construction and packaging to moldings for sprockets and skateboard wheels, polyurethane is extremely versatile as it can be manufactured to varying levels of hardness, stiffness, and density. Polyurethane is used widely due to its low tooling cost, resistance to abrasion and extensive wear, its excellent tear strength, color acceptability, elasticity, and solvent resistance. It also operates at minimal noise levels, can be cast, molded, and machined. It can be made sponge-soft or iron hard and can withstand extensive temperature changes. It is this versatility as well as its durability that makes polyurethane such a desirable material in so many industrial applications.

Polyurethane molding, in particular, offers incomparable durability in a lightweight substance. This combination is ideal as decreased weight without sacrificing strength is often a key to economic success in applications such as construction and transportation. In addition to combining the advantageous qualities of rubber, metal, and plastic, polyurethane molding products are also resistant to high temperatures and pressures. This means a long working life with little wear and tear. For instance, sprockets in conveyor belting are made to tight-tolerances and must maintain strength under continual use at high temperatures. Polyurethane moldings are used predominately for sprockets like these because of their long term durability.

Polyurethane molding, in particular, offers incomparable durability in a lightweight substance. This combination is ideal as decreased weight without sacrificing strength is often a key to economic success in applications such as construction and transportation. In addition to combining the advantageous qualities of rubber, metal, and plastic, polyurethane molding products are also resistant to high temperatures and pressures. This means a long working life with little wear and tear. For instance, sprockets in conveyor belting are made to tight-tolerances and must maintain strength under continual use at high temperatures. Polyurethane moldings are used predominately for sprockets like these because of their long term durability.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

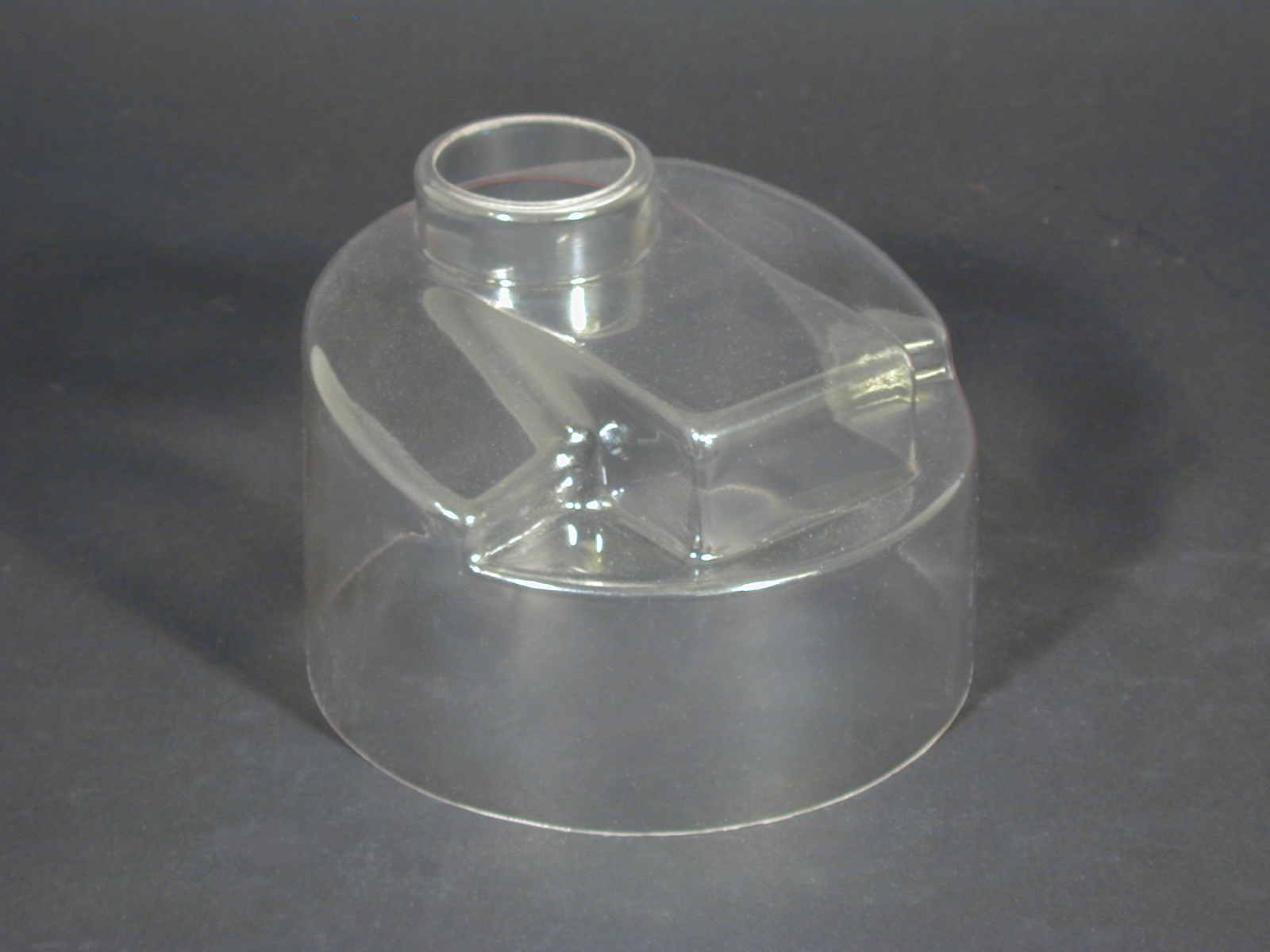

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

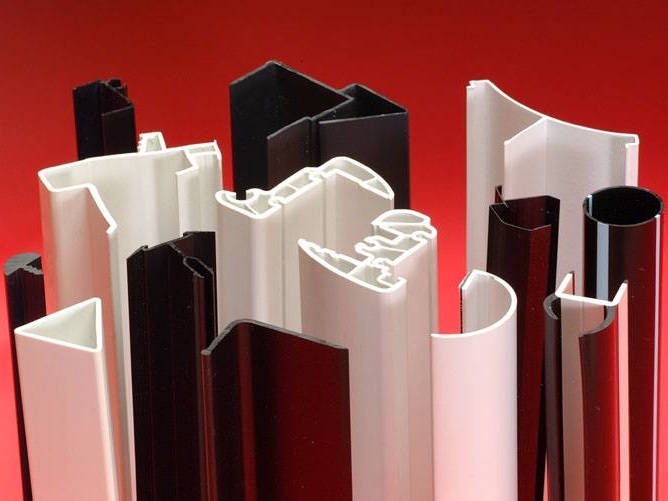

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services