Tandem Products, Inc.

Tandem Products, Inc.

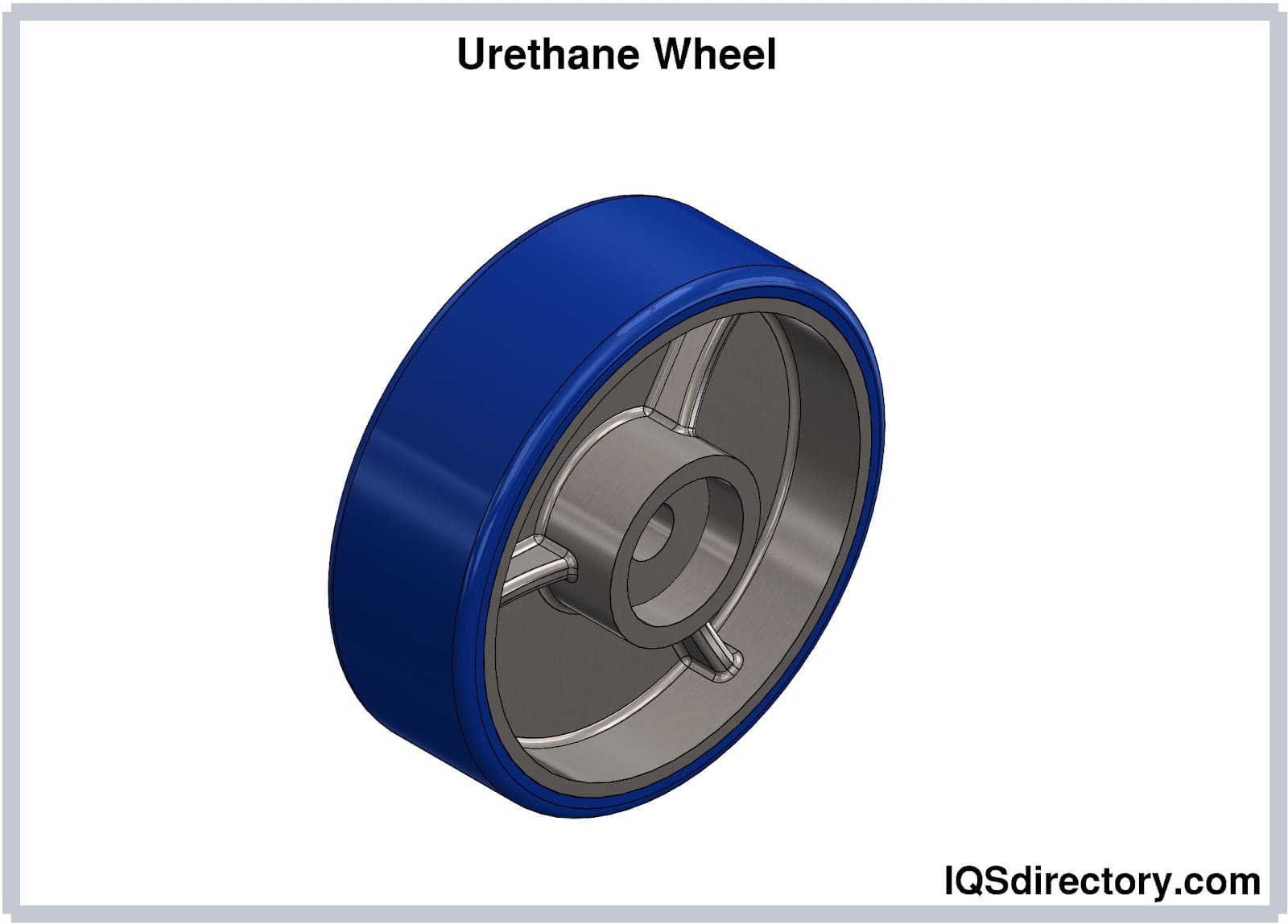

Minneapolis, MNTandem Products, Inc. is a leading manufacturer of high-quality molded urethane products, specializing in providing customized solutions that meet the unique needs of its customers. With over 35 years of experience in the industry, Tandem Products, Inc. has established itself as a trusted and reliable partner for businesses across a wide range of industries. Tandem Products' molded urethane products are known for their exceptional mechanical properties, including high strength, durability, and resistance to wear and tear. The company uses advanced manufacturing processes and equipment to ensure that its products are of the highest quality and meet the strictest industry standards. One of the key strengths of Tandem Products, Inc. is its extensive service capabilities. The company provides a wide range of services, including product design and development, prototyping, testing, and manufacturing. Tandem Products' team of experienced engineers and technical experts works closely with customers to develop custom solutions that meet their unique needs and requirements. Tandem Products' molded urethane products are used in a variety of industries, including agriculture, mining, and material handling. In the agriculture industry, Tandem Products' molded urethane products are used in a range of applications, including conveyor belts, grain cart spouts, and seed tube guards. These products offer superior performance, durability, and resistance to harsh environmental conditions, helping to improve the efficiency and reliability of agricultural equipment. In the mining industry, Tandem Products' molded urethane products are used in a variety of applications, including conveyor belt skirting, slurry pump liners, and chute liners. These products offer superior performance, durability, and resistance to abrasive materials, helping to improve the longevity and efficiency of mining equipment. In the material handling industry, Tandem Products' molded urethane products are used in a variety of applications, including rollers, wheels, and bumpers. These products offer superior performance, durability, and resistance to wear and tear, helping to improve the efficiency and safety of material handling equipment. Overall, Tandem Products, Inc. is a trusted and reliable provider of high-quality molded urethane products and services. With its extensive experience and expertise, the company is well-positioned to meet the evolving needs of its customers and provide innovative solutions that drive business success.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

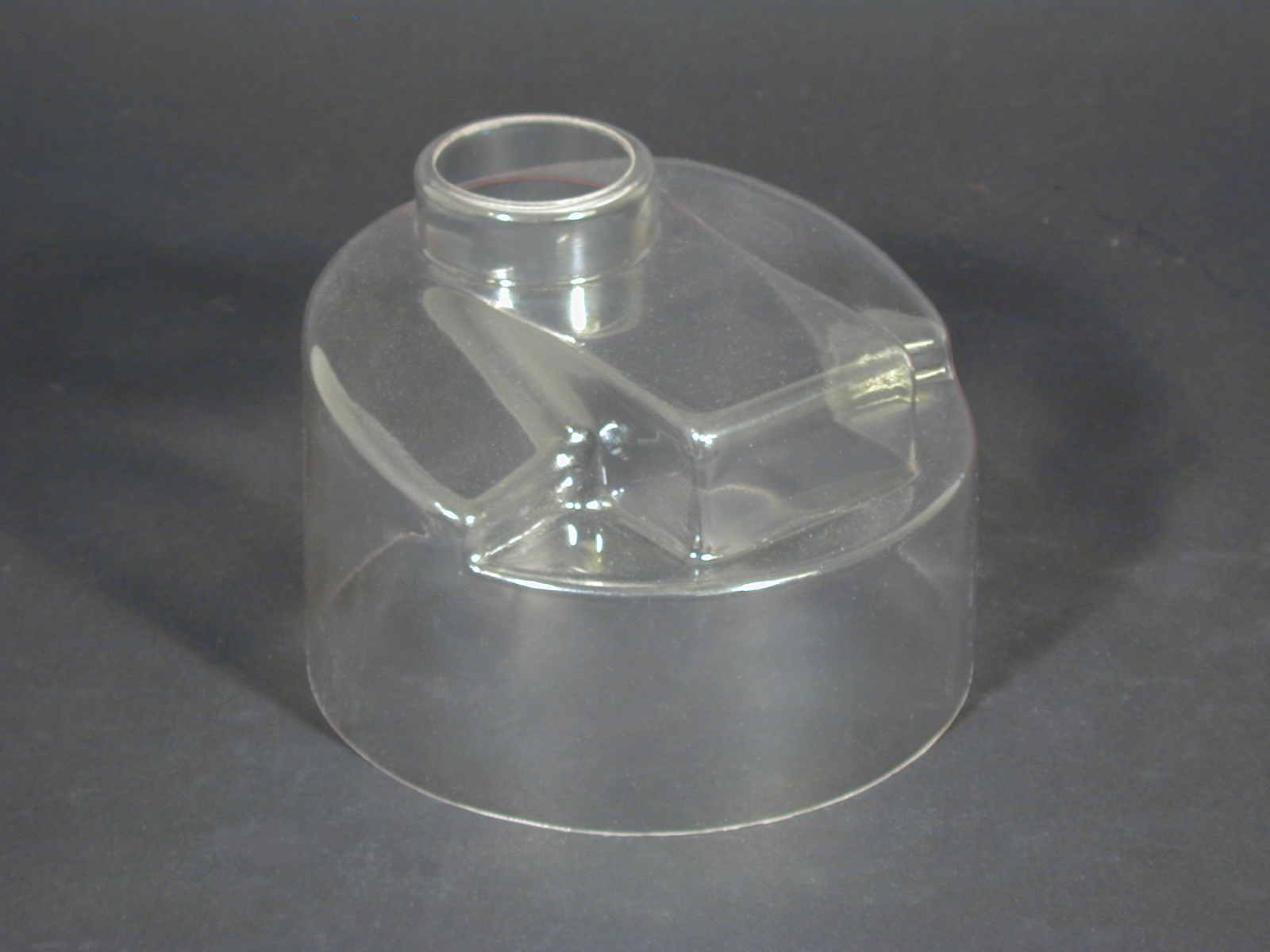

Plastic Blow Molding Plastic Dip Molding

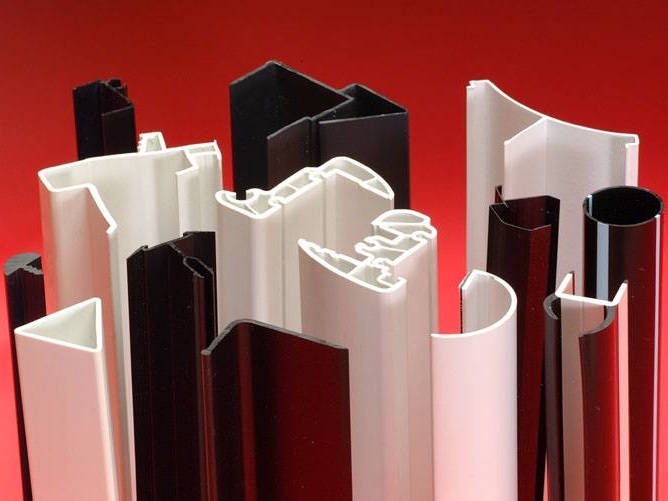

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

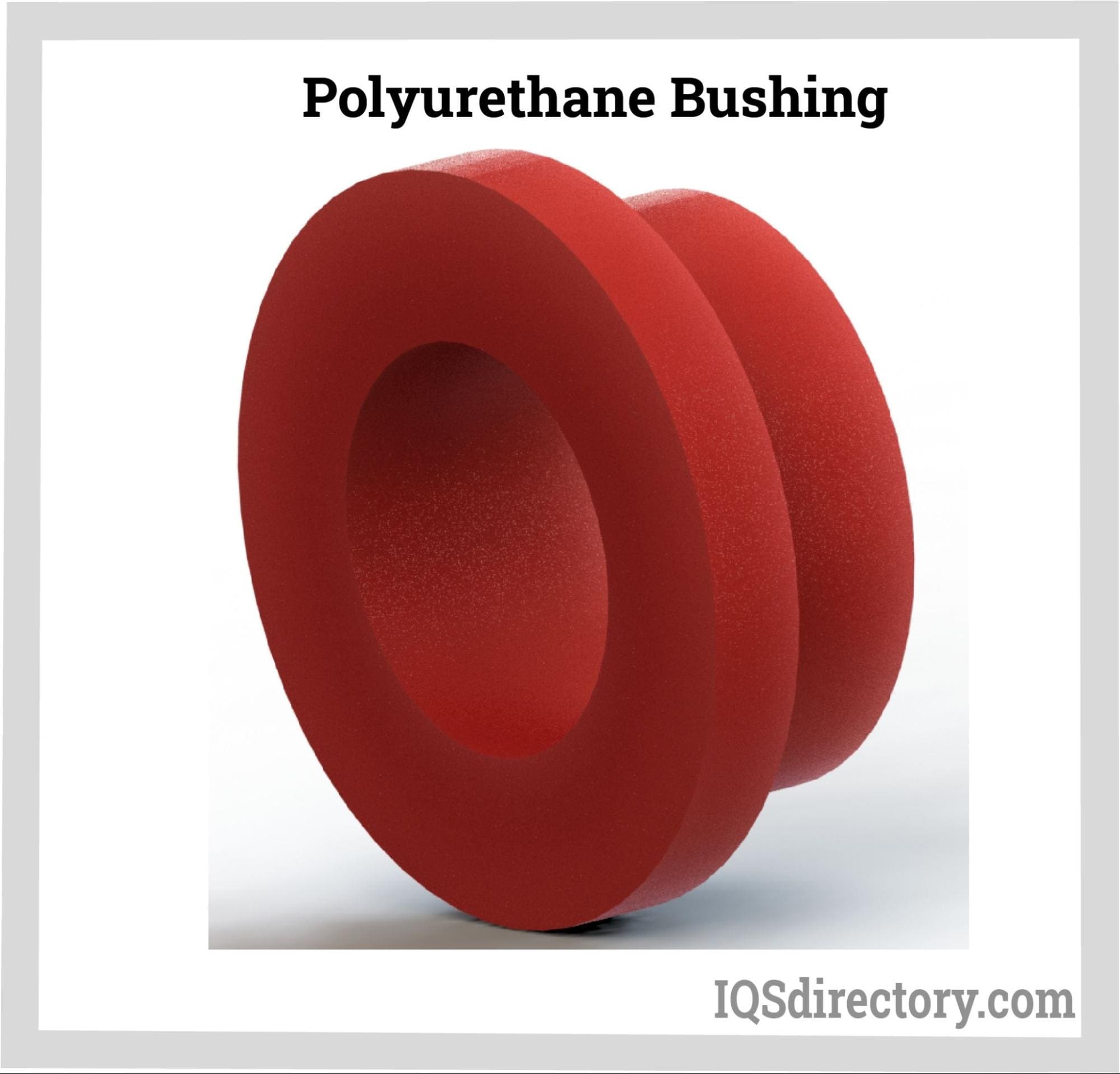

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services