Rhino Linings USA, Inc.

Rhino Linings USA, Inc.

San Diego, CARhino Linings USA, Inc. is a leading manufacturer of protective coatings and linings for industrial, commercial, and retail applications. Founded in 1988, the company is headquartered in San Diego, California, and has a global network of more than 2,000 licensed applicators and distributors in over 80 countries. Rhino Linings is best known for its sprayed-on polyurethane and polyurea coatings, which provide excellent protection against impact, abrasion, and corrosion. In addition to its sprayed-on coatings, Rhino Linings also offers a range of molded urethane products, which are custom-designed and fabricated to meet the specific needs of each customer. These products are made from a specialized blend of urethane materials, which are formulated to provide exceptional durability and resistance to wear and tear. Rhino Linings' molded urethane products are used in a variety of industries, including mining, transportation, construction, and agriculture. Some of the company's most popular products include: Conveyor Rollers: Rhino Linings manufactures custom-molded conveyor rollers that are designed to withstand the harsh conditions of mining and other heavy-duty applications. These rollers are available in a range of sizes and configurations, and can be customized to meet the specific needs of each customer. Pipe Liners: Rhino Linings' molded urethane pipe liners provide excellent protection against abrasion and corrosion in pipelines and other industrial applications. These liners are designed to be easy to install and maintain, and can help extend the life of pipelines and other equipment. Impact Bars: Rhino Linings' molded urethane impact bars are used to protect conveyor belts and other equipment from impact damage. These bars are designed to absorb the energy of impact and distribute it evenly, reducing the risk of damage and downtime. Screen Panels: Rhino Linings manufactures custom-molded screen panels that are used in mining and other industrial applications to separate and classify materials. These panels are available in a range of sizes and configurations, and can be customized to meet the specific needs of each customer. In addition to its molded urethane products, Rhino Linings also offers a range of services to support its customers. These services include: Design and Engineering: Rhino Linings' team of experienced engineers can work with customers to design custom-molded urethane products that meet their specific needs. The company uses advanced design software and 3D printing technology to create prototypes and test designs before manufacturing. Manufacturing: Rhino Linings operates state-of-the-art manufacturing facilities in the United States and around the world. The company uses advanced molding and casting techniques to produce high-quality urethane products that meet the most demanding specifications. Application: Rhino Linings has a global network of more than 2,000 licensed applicators and distributors who are trained to apply its sprayed-on coatings and install its molded urethane products. These professionals are trained to ensure that Rhino Linings' products are installed correctly and perform as expected. In summary, Rhino Linings USA, Inc. is a leading manufacturer of protective coatings and linings for industrial, commercial, and retail applications. The company's molded urethane products are custom-designed and fabricated to meet the specific needs of each customer, and are used in a variety of industries. Rhino Linings also offers a range of services to support its customers, including design and engineering, manufacturing, and application.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

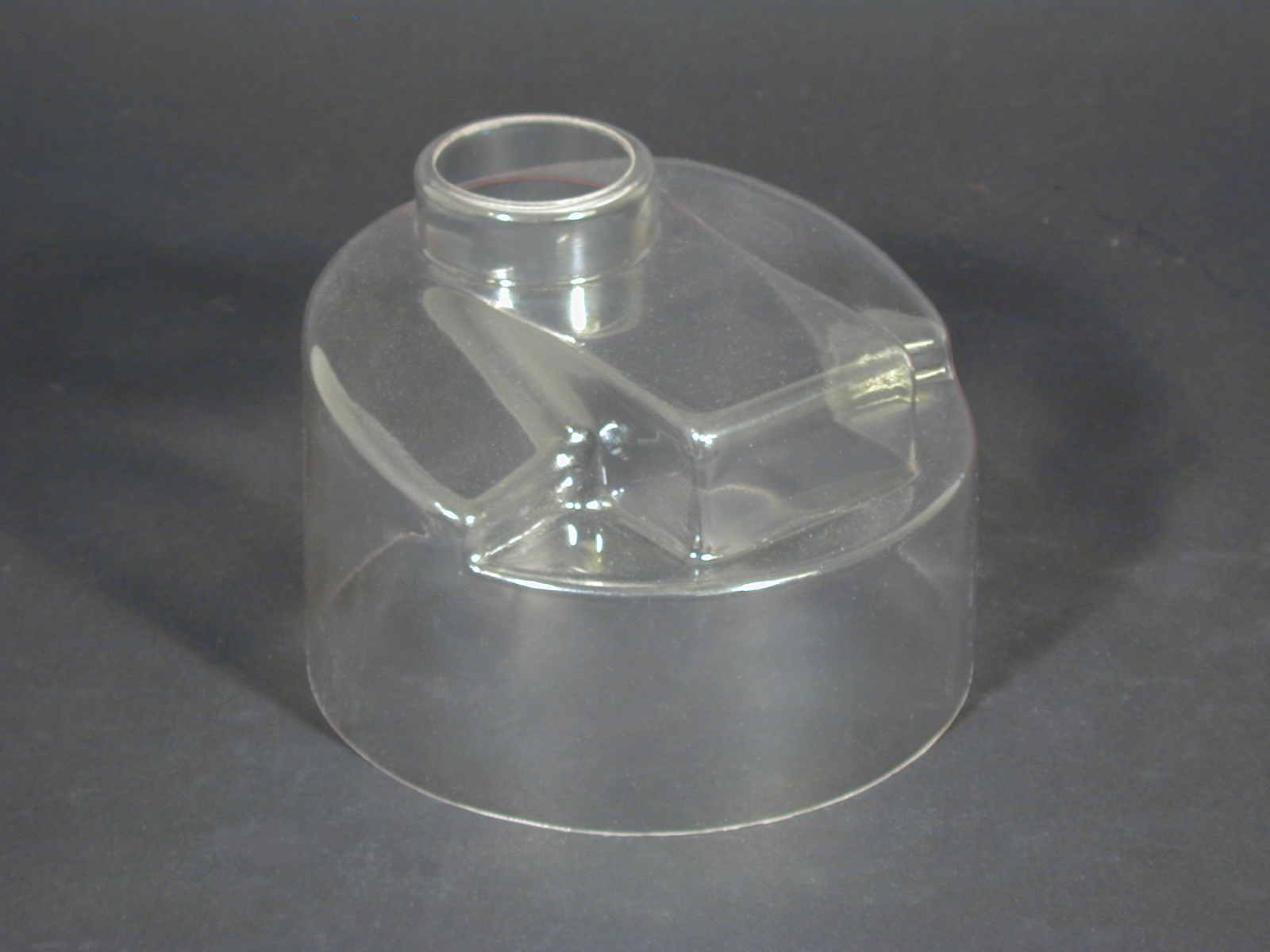

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

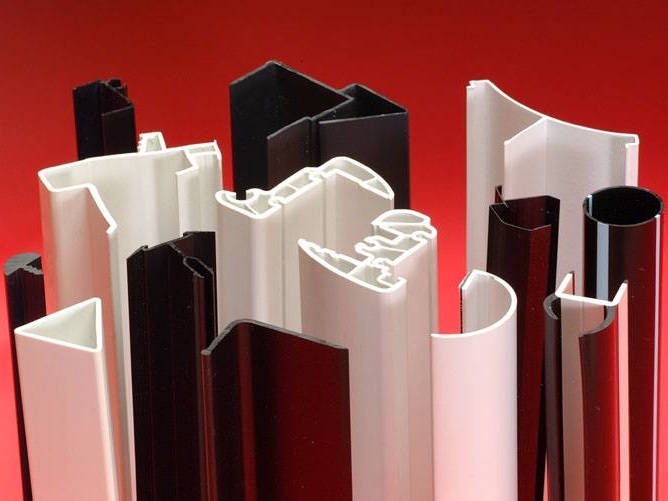

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

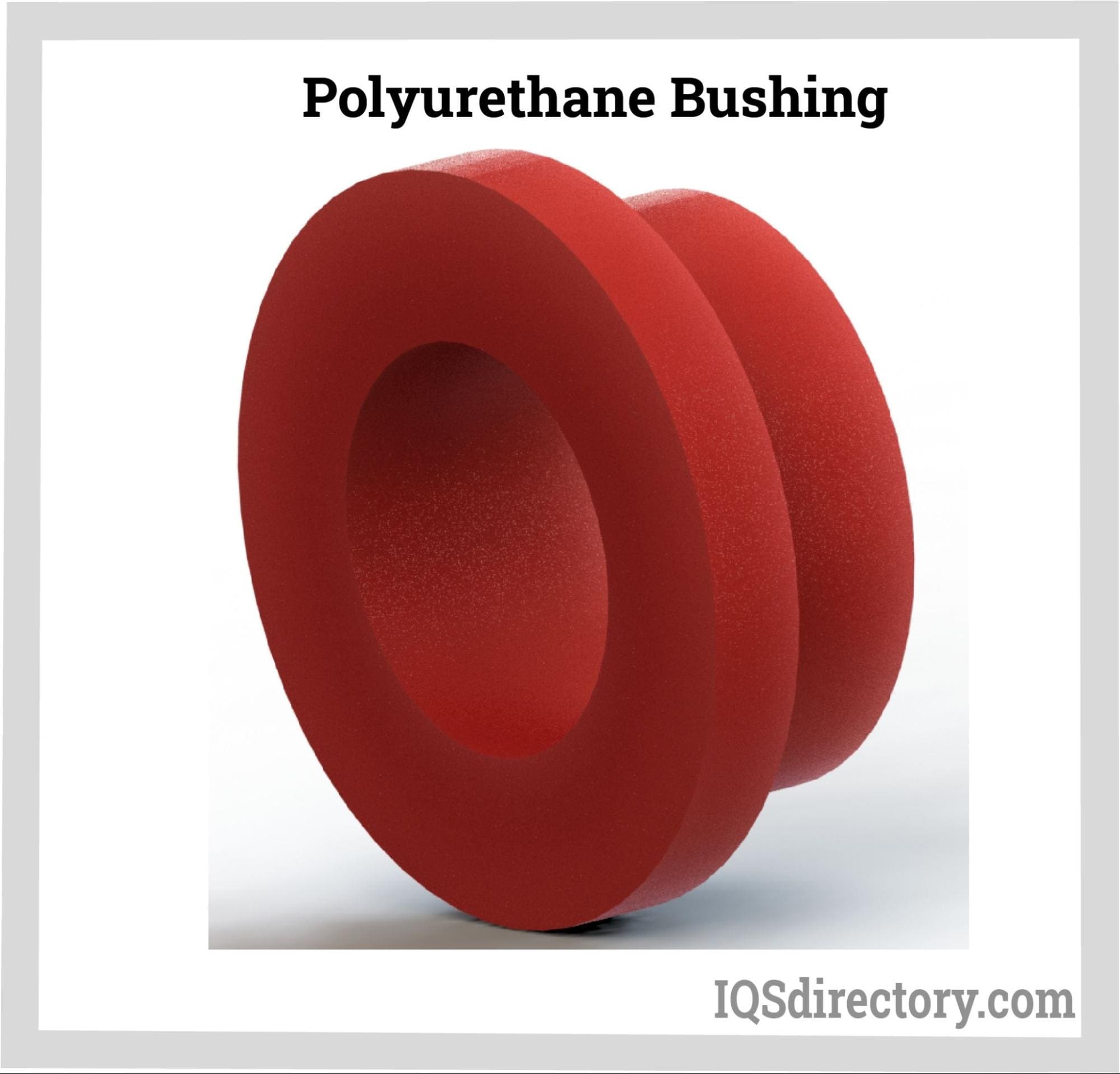

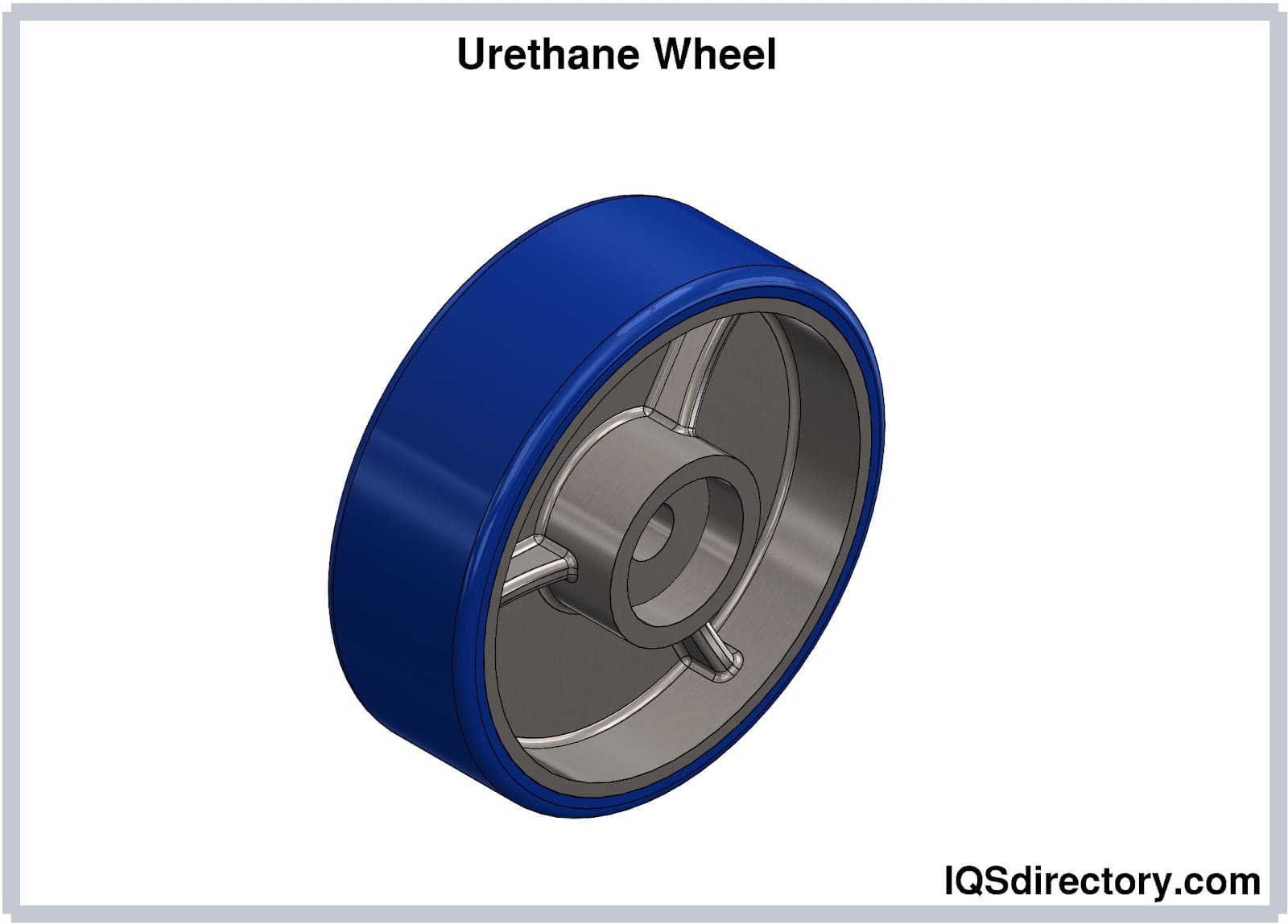

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services