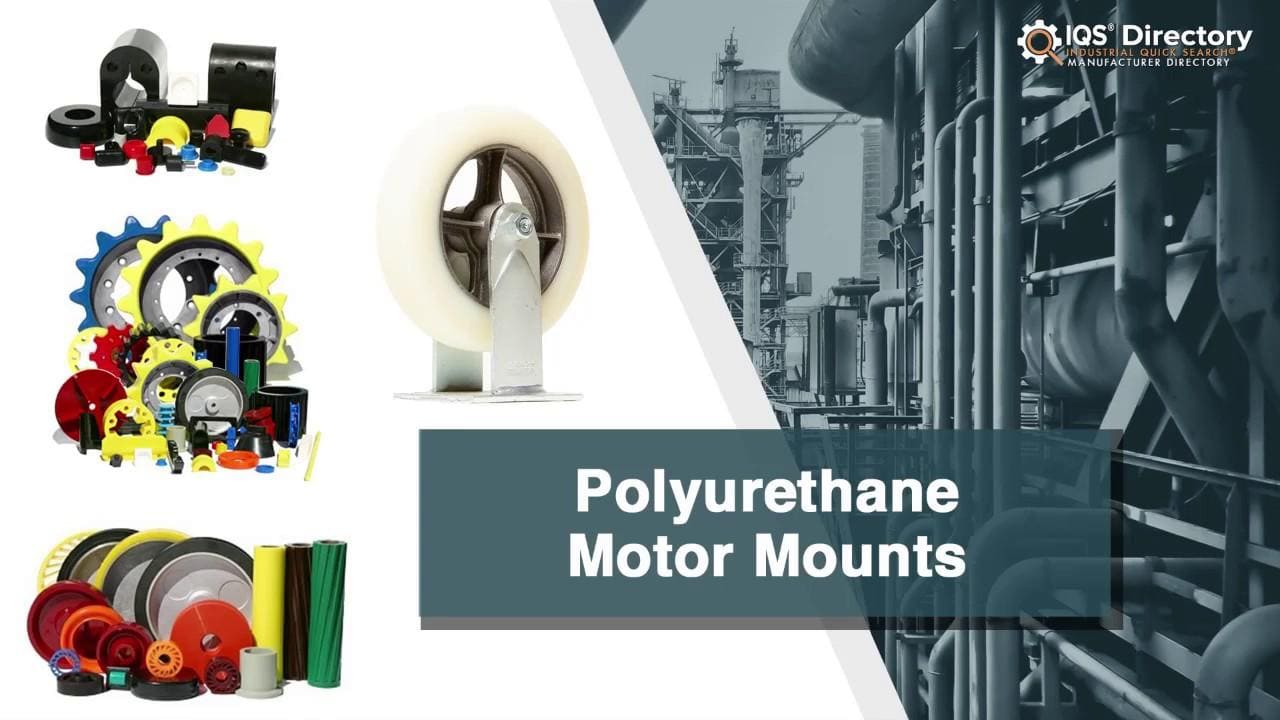

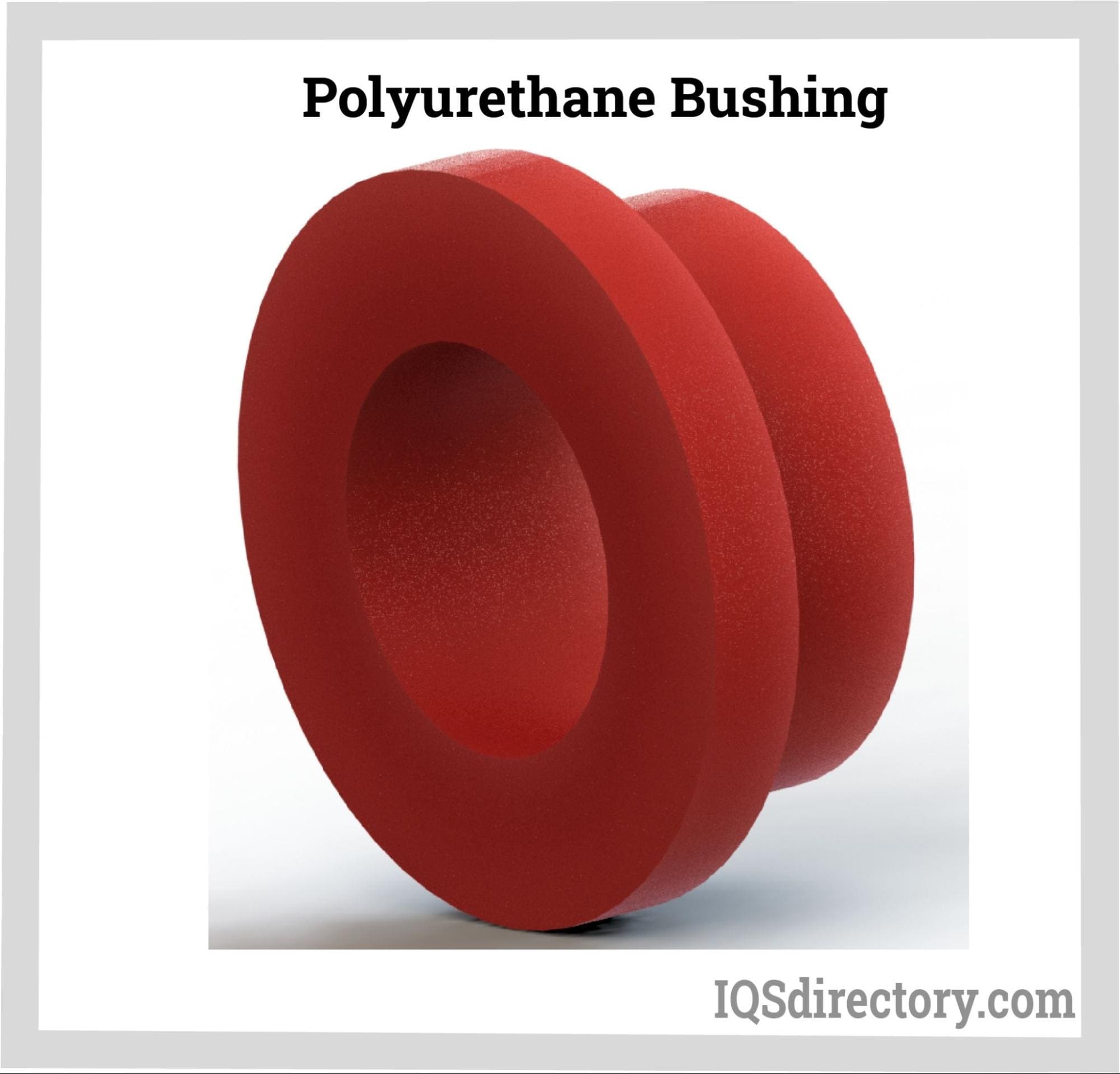

Polyurethane motor mounts are devices used to anchor an object to remain firm in its operating position. Mounts control the transfer of vibration and noise. Polyurethane motor mounts help minimize flexing in components, which are crucial to prevent wear and tear. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

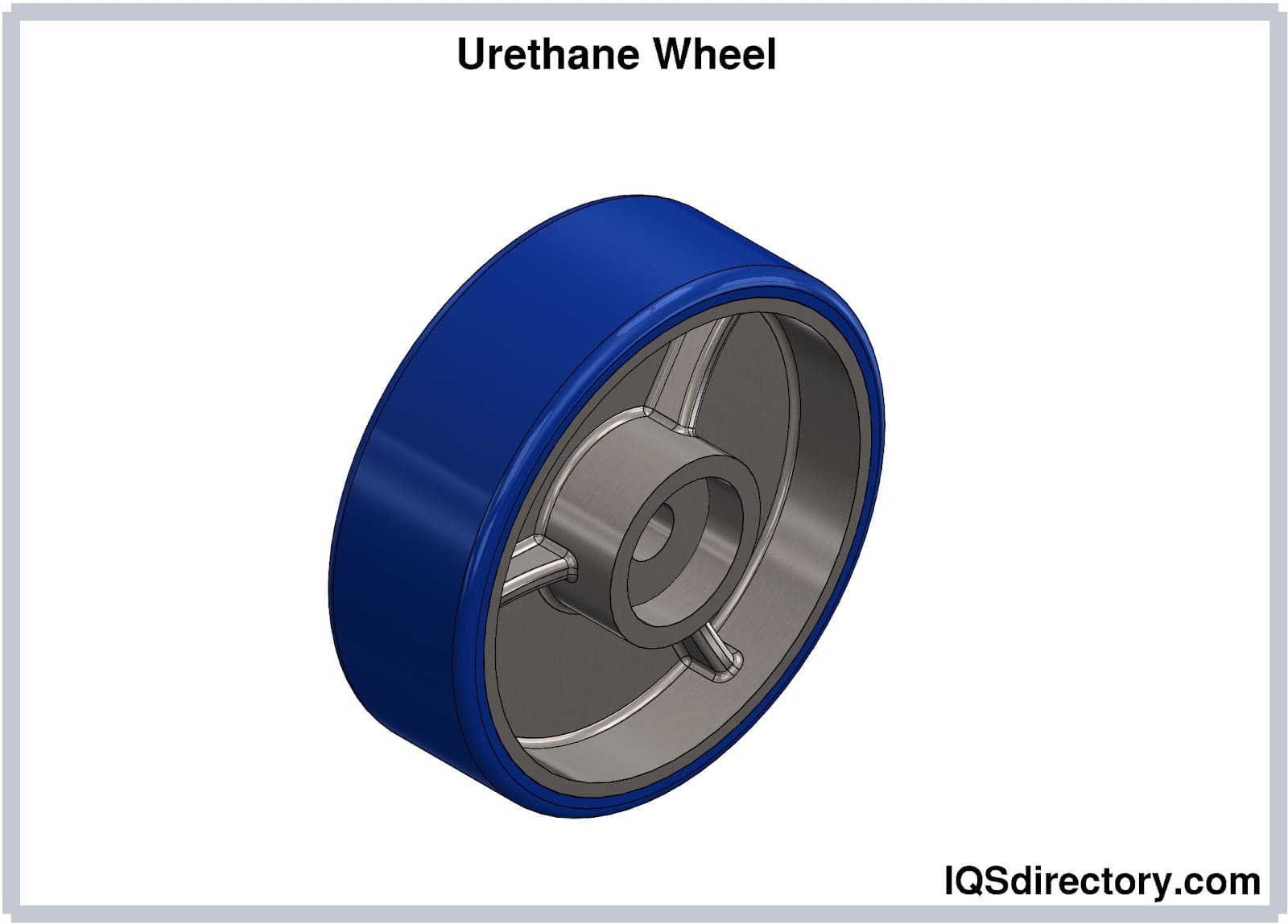

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

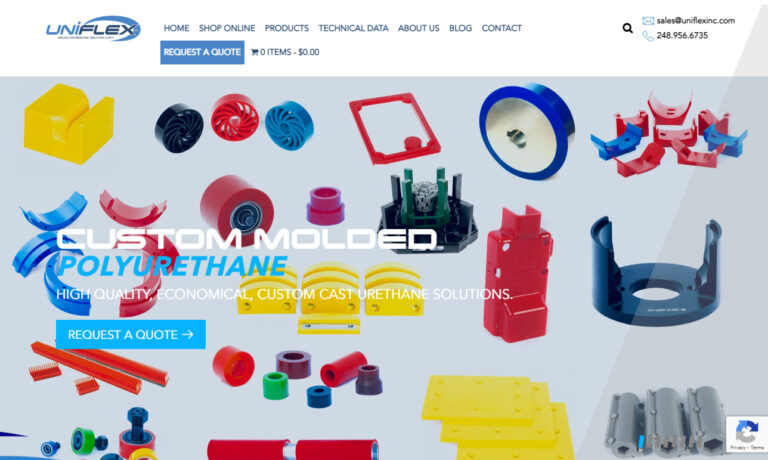

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is...

More Polyurethane Motor Mount Companies

What Is a Polyurethane Motor Mount?

Polyurethane motor mounts are devices used to anchor an object to remain firm in its operating position. Mounts control the transfer of vibration and noise. Polyurethane motor mounts help minimize flexing in components, which are crucial to prevent wear and tear.

These types of mounts have several advantages over those of rubber. This is because they have excellent resistance to extreme temperatures and abrasion.

Materials Used In Manufacturing Mounts

Polyurethane is the material used to make polyurethane mounts. It is defined as a polymer that is organic and petroleum-based. The organic compound consists of molecules that are cross-linked by a process known as thermoset cross-linking.

Thermoset cross-linking will make a compound not suitable for reuse or melting. As a result, the material will have superior and greater physical properties than thermoplastic materials.

However, they have an optimum temperature range, so high heat compatibility should be considered.

How Polyurethane Mounts Are Manufactured

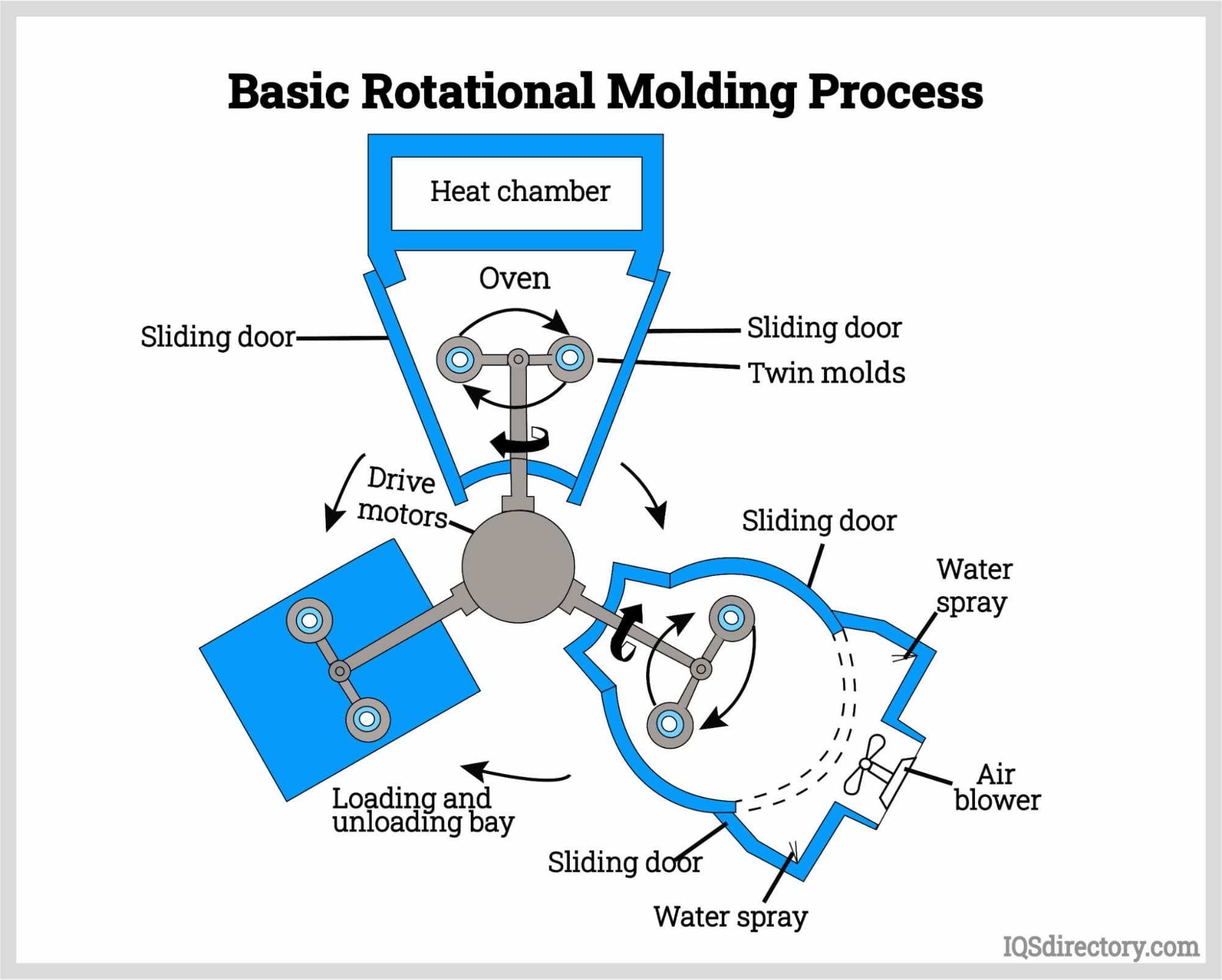

Master mold is the method initially used to come up with the shape of the mount from the molds. Very large quantities and short runs are catered for by this master mold method. Another benefit of the master mold procedure is that it is less costly. Another benefit of the master mold procedure is that it is less costly.

This process is followed by machining the polyurethane, which is dispensed in a liquid. The machining process takes place in a conveyor oven with a temperature of approximately 250 °F (121 °C).

The third stage in manufacturing polyurethane mounts involves curing the urethane in the hot oven into a solid state. Finally, once the curing process is done, the polyurethane is brought out of the mold and taken to the post-cure ovens for a day at temperatures of 250 °F (121 °C).

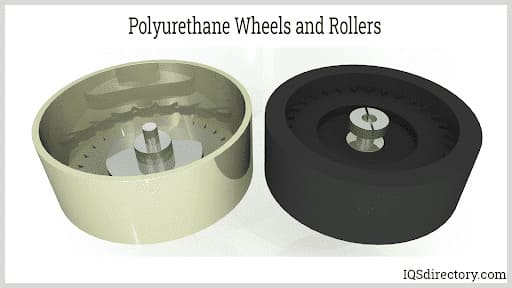

Types of Polyurethane Mounts

The types of polyurethane mounts include:

Polyurethane Transfer Mounts

Polyurethane transfer mounts protect expensive drive trains by minimizing dangerous vibrations and bending. Polyurethane transfer mounts are much more resistant to abrasion, grease, and oil. They have a long life span compared to rubber mounts.

Polyurethane Exhaust Hangers

These have much greater resistance to road debris and vibrations. In addition, they have the major benefit of withstanding very high temperatures. Polyurethane exhaust hangers are considered alternatives for those made of steel or rubber.

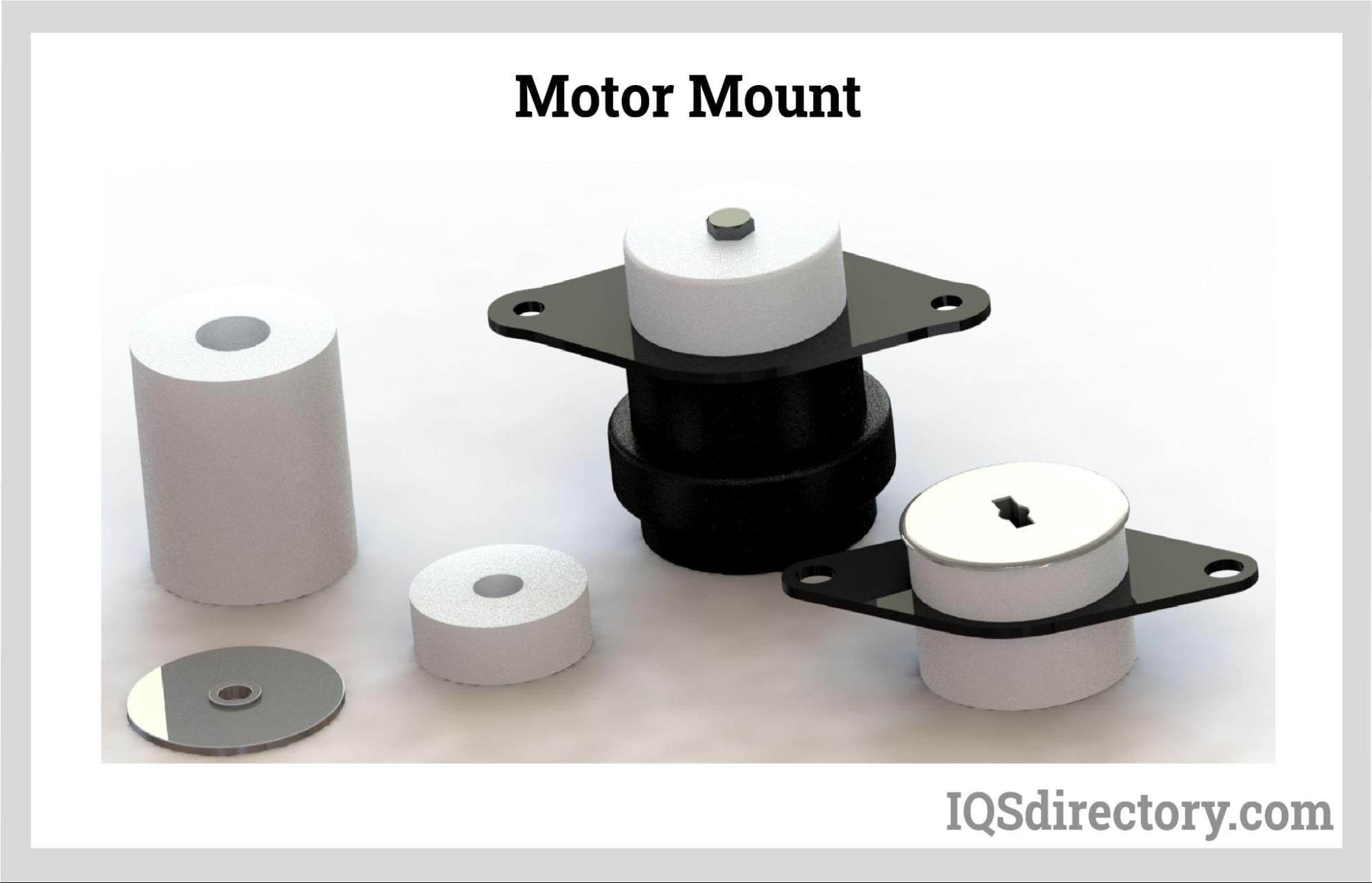

Motor Mounts

Motor mounts provide the appropriate stabilizers needed for automobile engines. Motor mounts help to reduce the vibrations that occur due to the process of internal combustion.

Transmission Mounts

These are responsible for isolating vibrations. In addition, transmission mounts are needed to support the engine.

Body Mounts

Body mounts are the ones that make a connection between the body and the vehicle frame. They are responsible for the absorption of the driving vibrations and noise.

Frame Mounts

Frame mounts give great resistance to abrasion. They are reliable because they provide enough space for the art.

Marine Motor Mounts

The marine motor mounts are specifically for engines that operate on open seas. They are made in such a way that they offer protection from saltwater by offering great resistance to degradation.

Poly Motor Mounts

They are used the same way as motor mounts. However, they are considered a much better choice than rubber mounts.

Universal Motor Mounts

The universal motor mounts have all the qualities needed for a standard mount combined.

Custom Motor Mounts

Custom motor mounts are made to produce more flexible and compression-resistant mounts. In addition, custom motor mounts can have adjustable hardness for the needed requirements.

Advantages and Uses of Polyurethane Motor Mount

Polyurethane motor mounts act as a dampener between the propeller shaft and gearbox. This helps to isolate the vibration from the gearbox and the engine. Also, motor mounts minimize the shock between the gear changes.

They also dampen noise and vibration produced by the propeller shaft. Polyurethane motor mounts are capable of withstanding both cold and high temperatures. They have great resistance to most chemicals, grease, oil, and coolants. They also do not crack.

Choosing the Correct Polyurethane Motor Mount Supplier

To make sure you have the most positive outcome when purchasing polyurethane motor mounts from a polyurethane motor mount supplier, it is important to compare at least 4 companies using our list of polyurethane motor mount suppliers. Each polyurethane motor mount supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each polyurethane motor mount company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple polyurethane motor mount companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

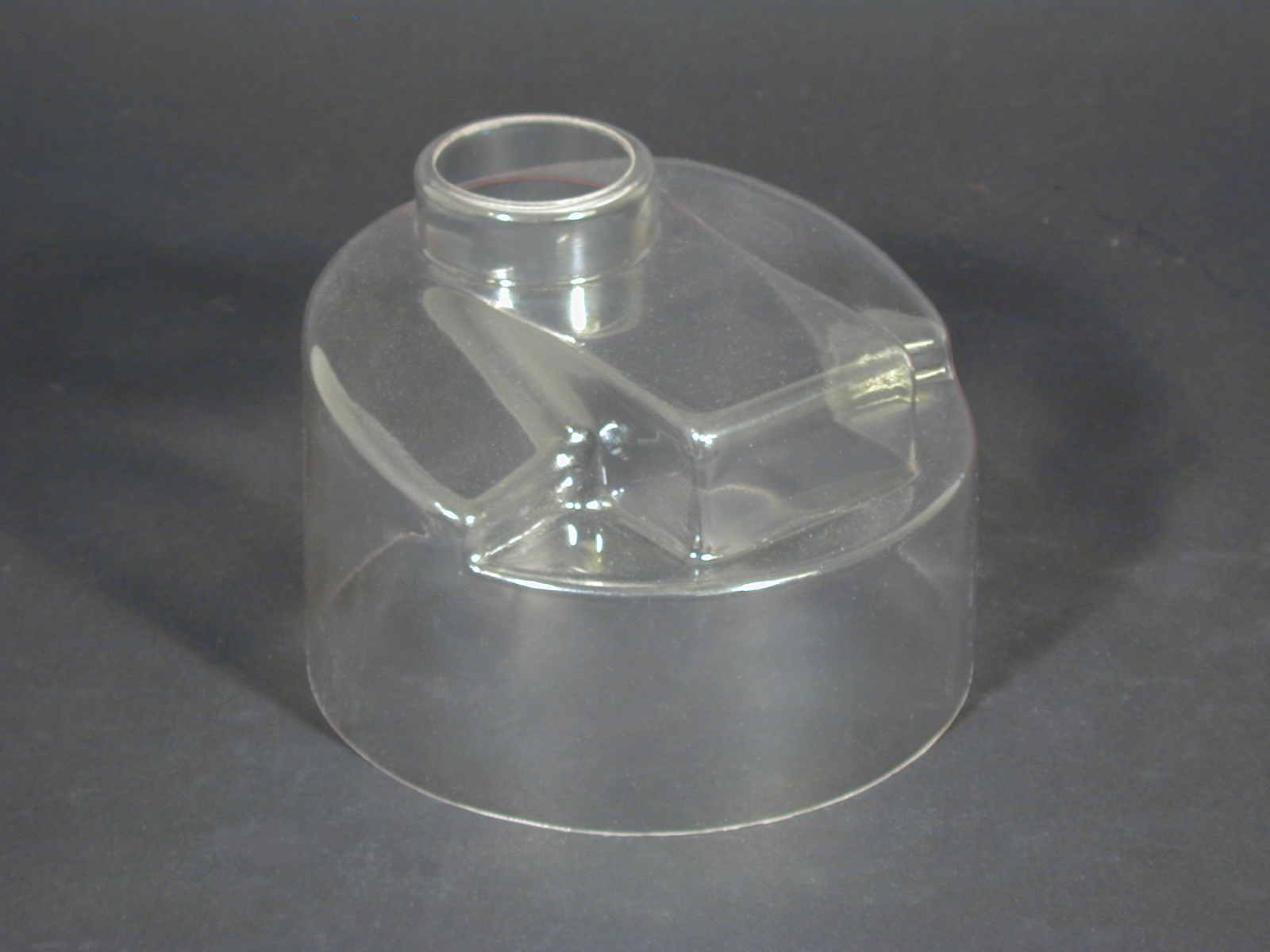

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

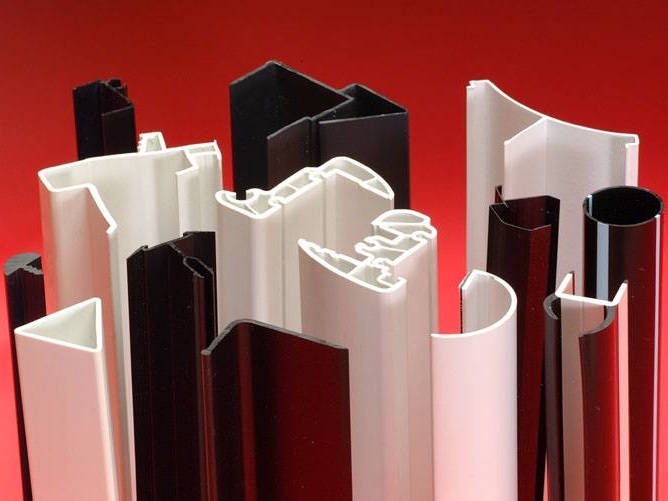

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services