Molded urethane is urethane that has been fabricated to form a part by introducing liquid urethane into a mold and allowing it to cure. Molded urethane products offer excellent flexibility and resistance to chemicals. They can be utilized for multiple industrial purposes, such as water treatment facilities, pressure transducers, and petroleum products. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

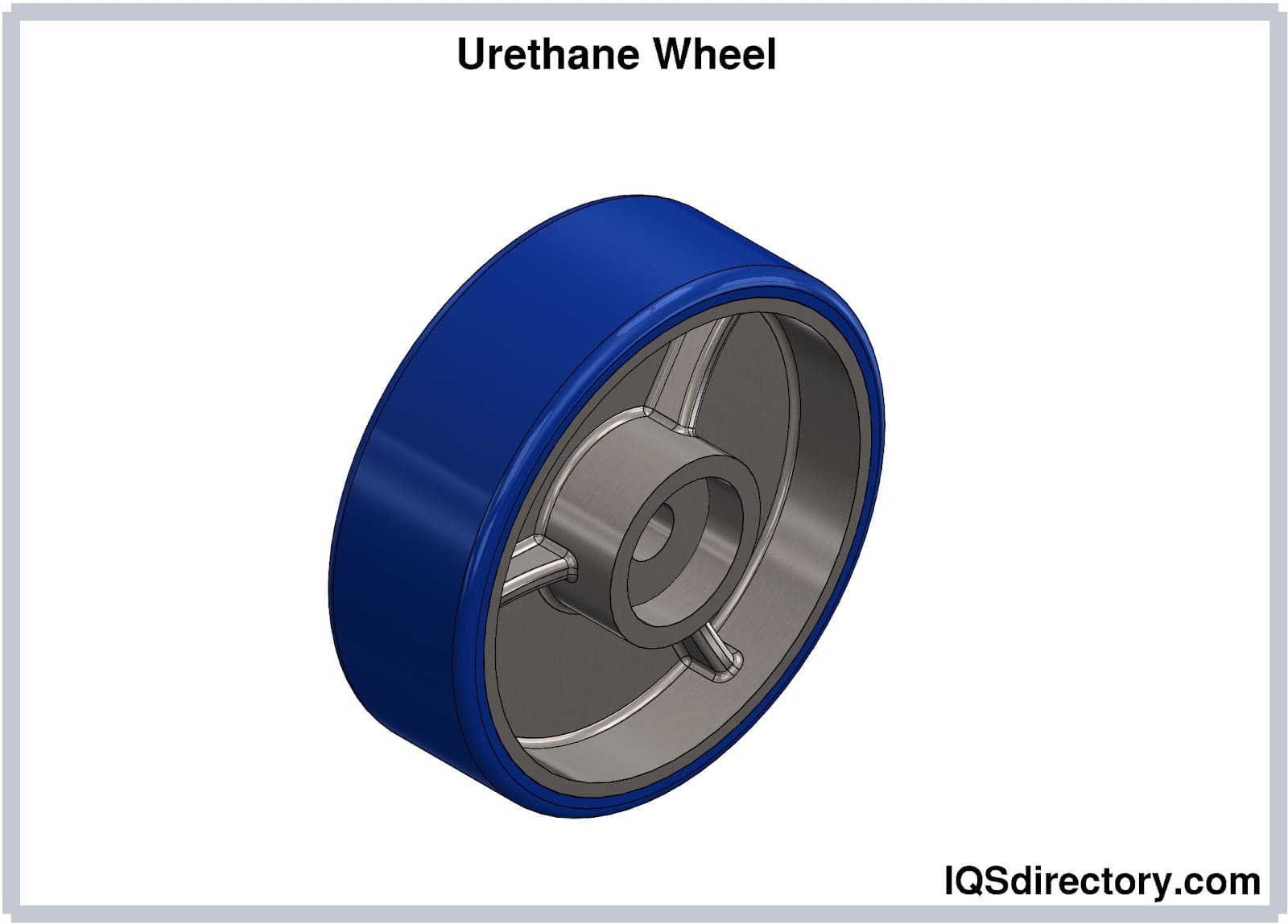

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

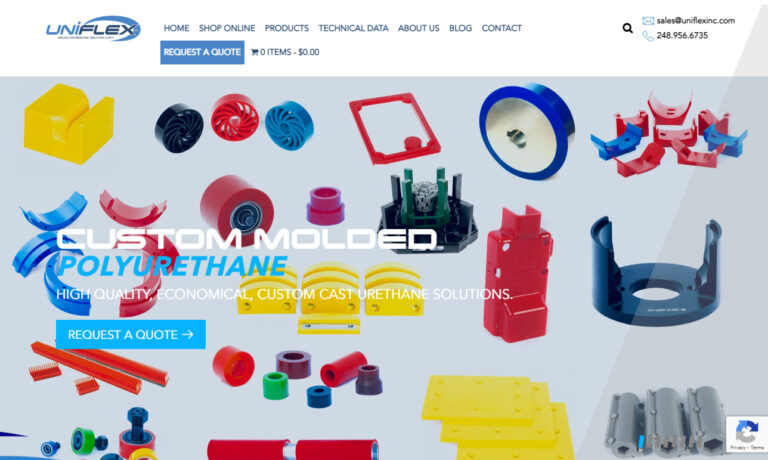

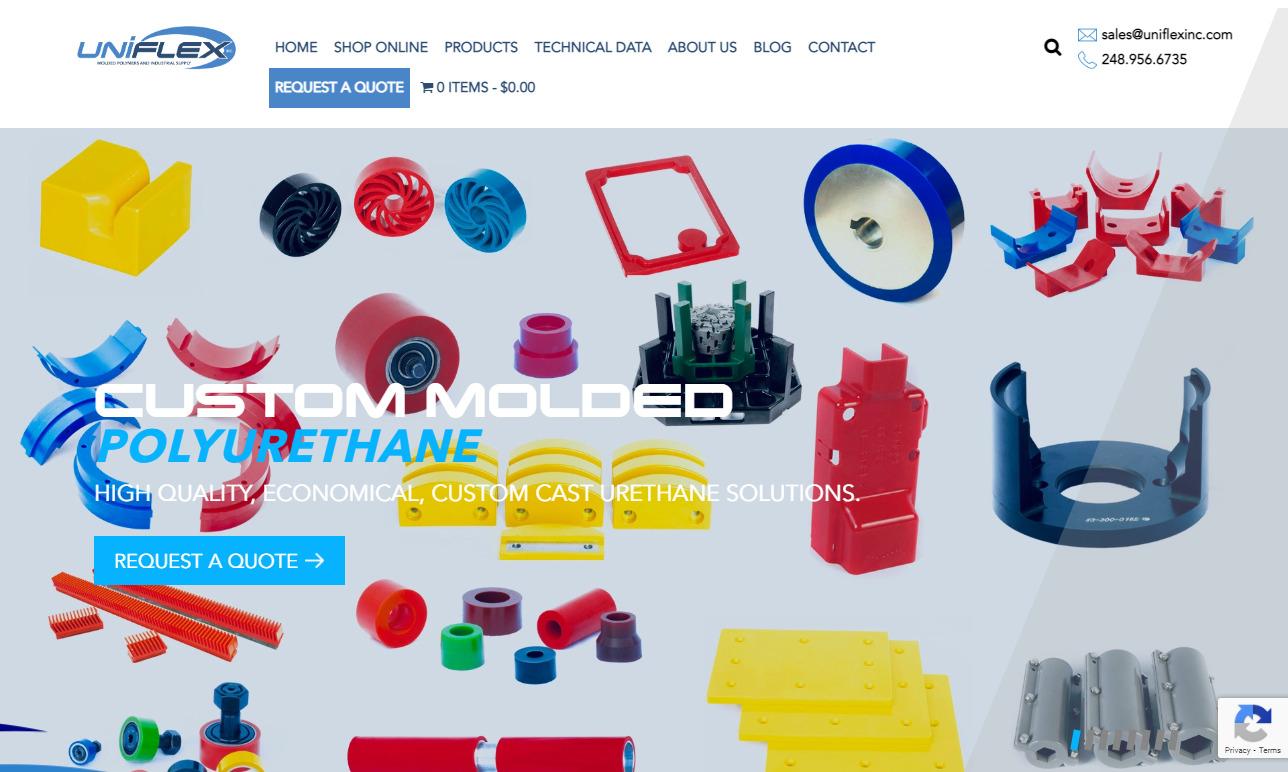

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

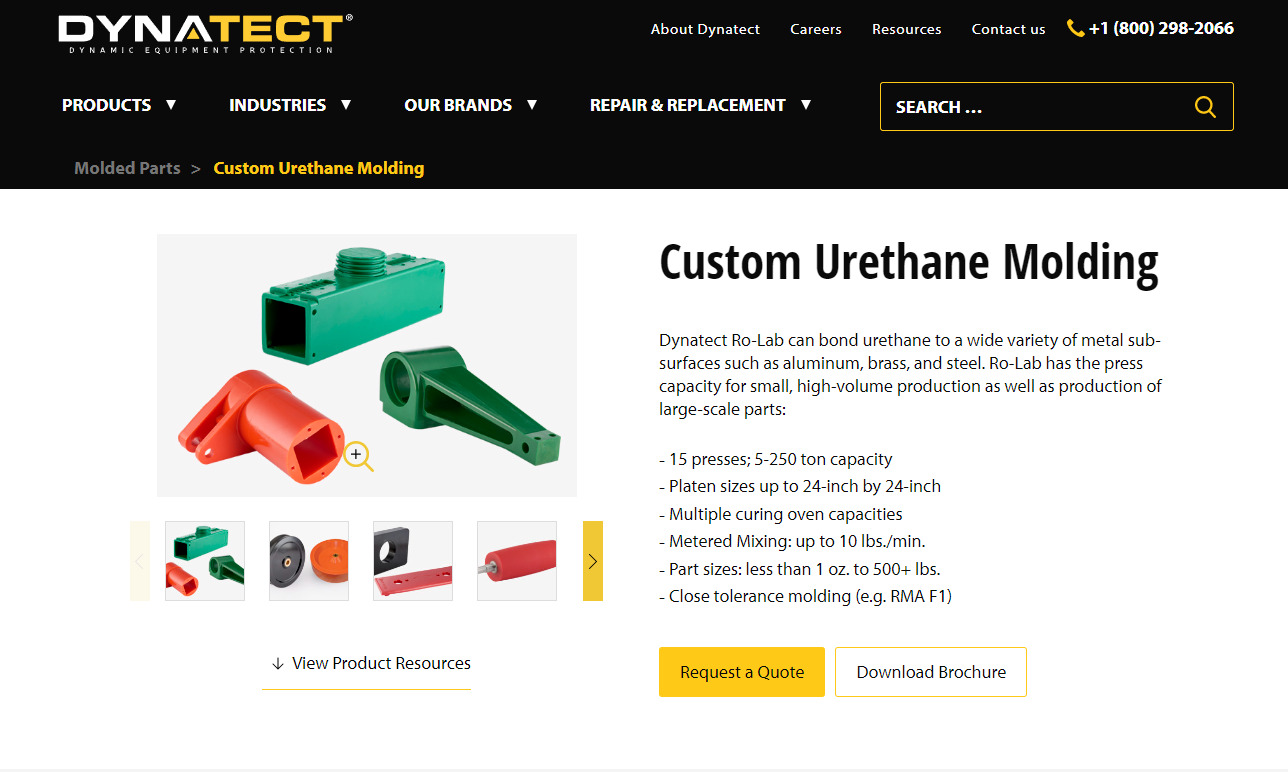

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is...

More Molded Urethane Companies

What is Molded Urethane?

Additives can be introduced to reduce friction, improve UV resistance, and increase flame retardation. Molded urethane products can also be utilized in small devices -- for example, washers -- to meet specific requirements.

Urethane appears as a white crystalline powder. For a reaction to occur, it must be first converted into its liquid state. After being converted into its liquid state, molded urethane products can be made by pouring or injecting liquid urethane into a mold containing the product.

When the reaction occurs, the urethane expands and hardens. To ensure lasting quality, it is necessary to carry out the curing process of the products in industrial ovens.

Molded Urethane Products

Some of the molded urethane products include:

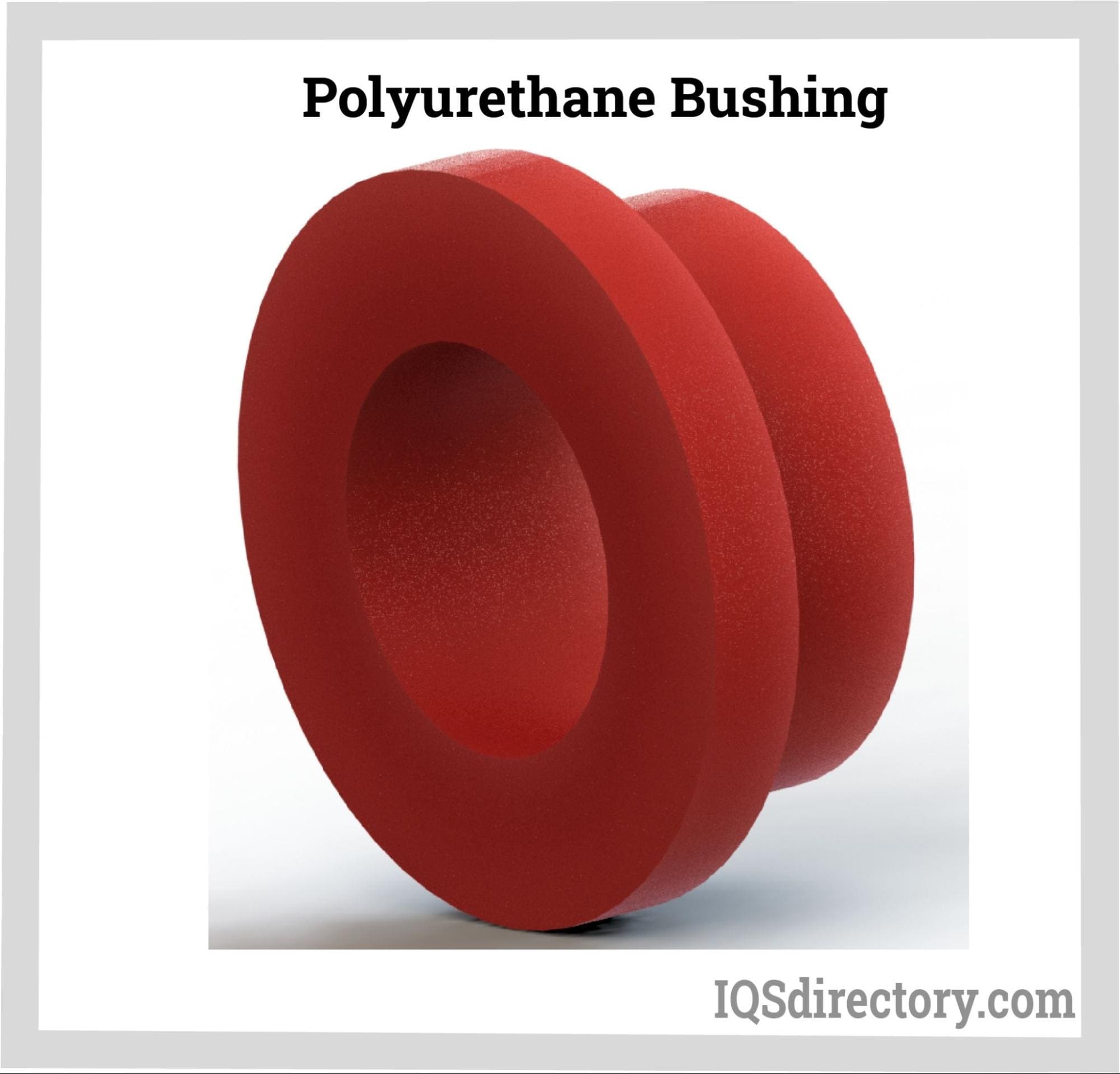

Molded Urethane Bushings

These bushings can be utilized in high-impact areas where the loads go beyond the capabilities of plastic and bronze. They are formulated using high-performance polymers.

Concrete Urethane Molds

These molds are durable and perfectly smooth. They are less expensive and exhibit higher abrasion resistance than molds made from silicon. Urethane concrete molds are very hard and do not shrink. Their abrasion resistance allows them to be used again and again.

Molded Urethane Shock Absorbing Pads and Mounts

Urethane is a compound ideal for use in vibration dampening and shock absorption. In addition, molded urethane has a wide range of hardnesses, making these products well-suited for applications like shock/vibration absorption.

Molded Urethane Rings

These products are manufactured from high-performance prepolymers. As a result, they can meet or exceed the highest standards, reducing downtime and costs for replacement.

Types of Molded Urethane

Some types of molded urethane include:

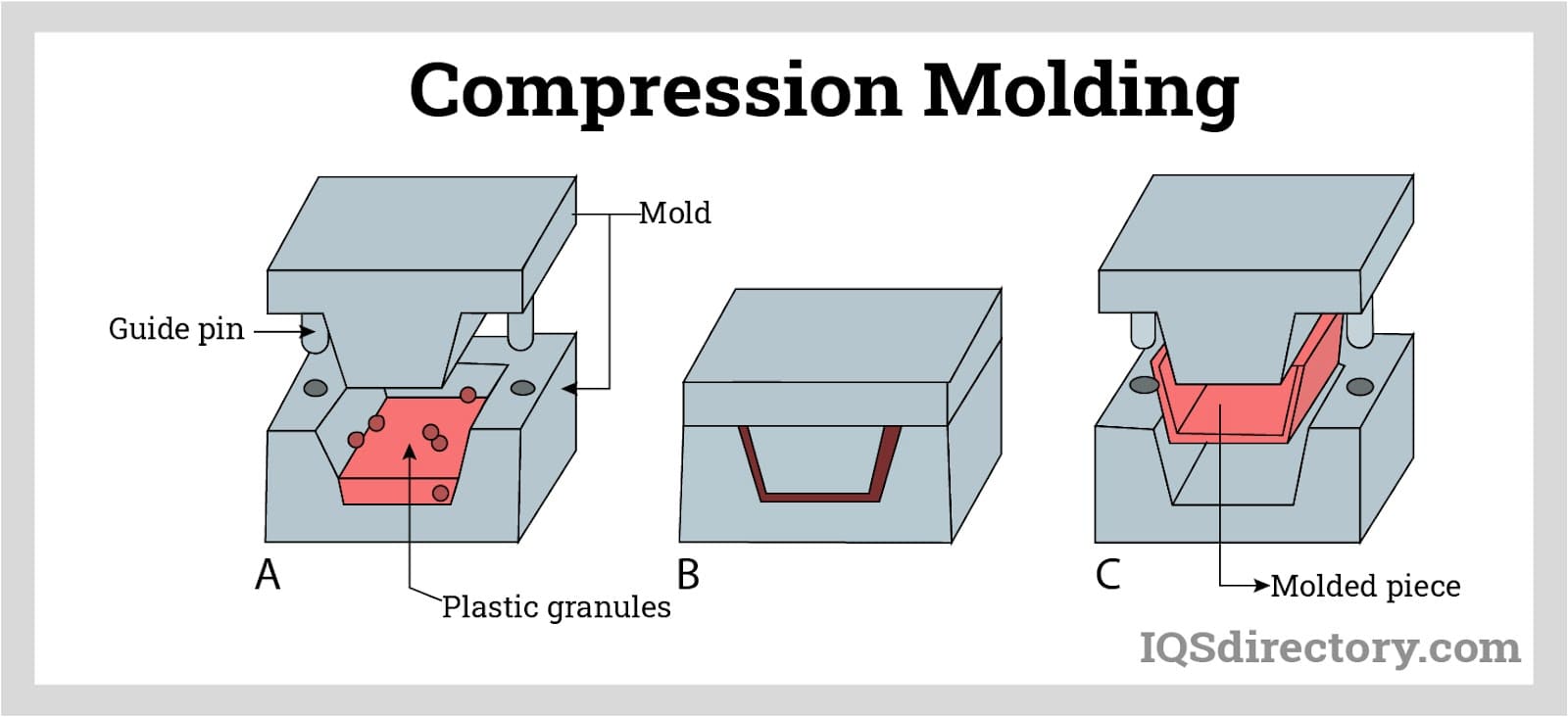

Compression Molded Urethane

This type of molded urethane is produced by pouring liquid urethane into a mold and allowing it to cure inside a compression press. This technique is well suited for components that must maintain dimensional accuracy and repeatability. Molded urethane produced through compression is rigid, flexible, resistant to wear, and durable.

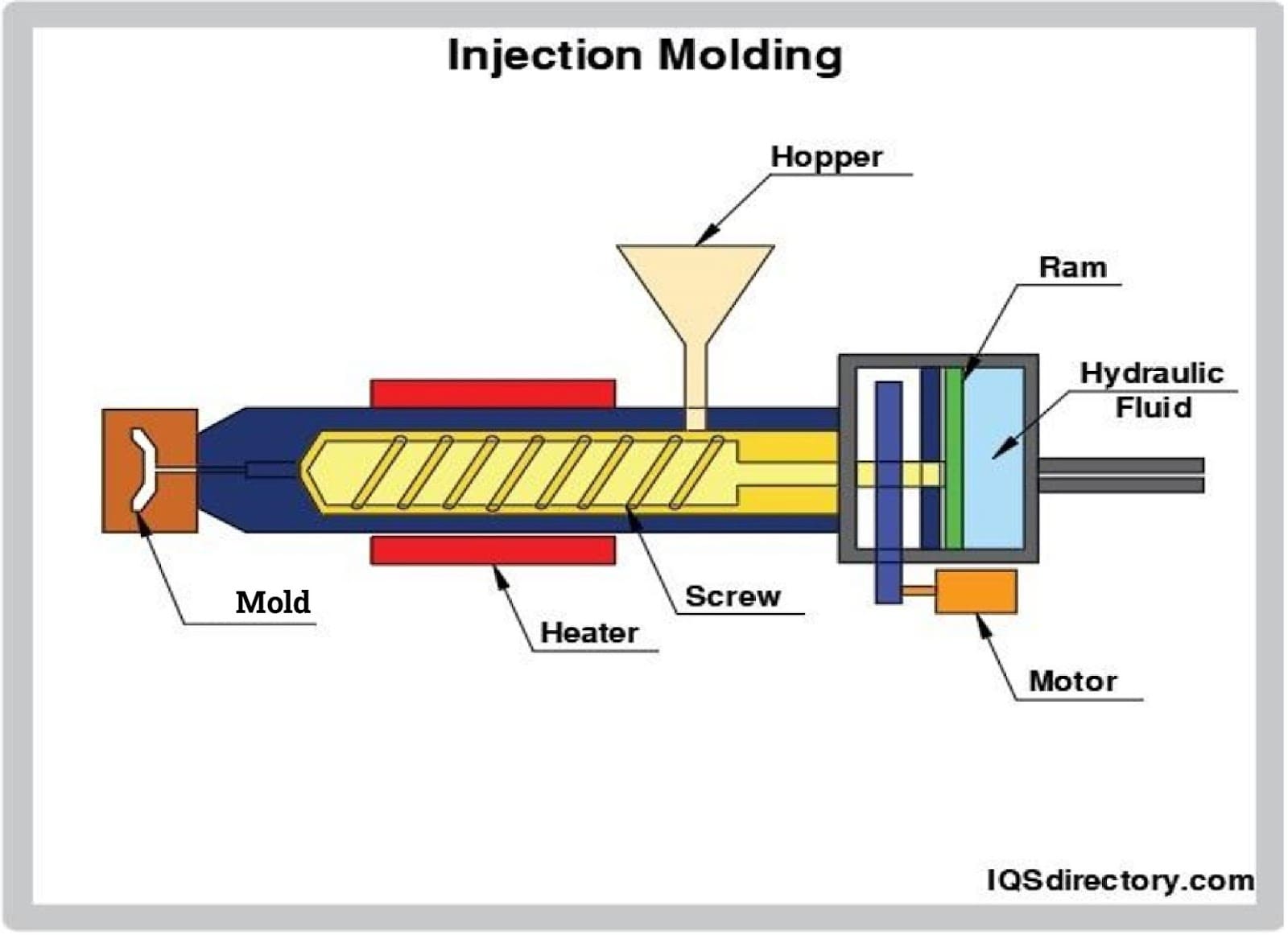

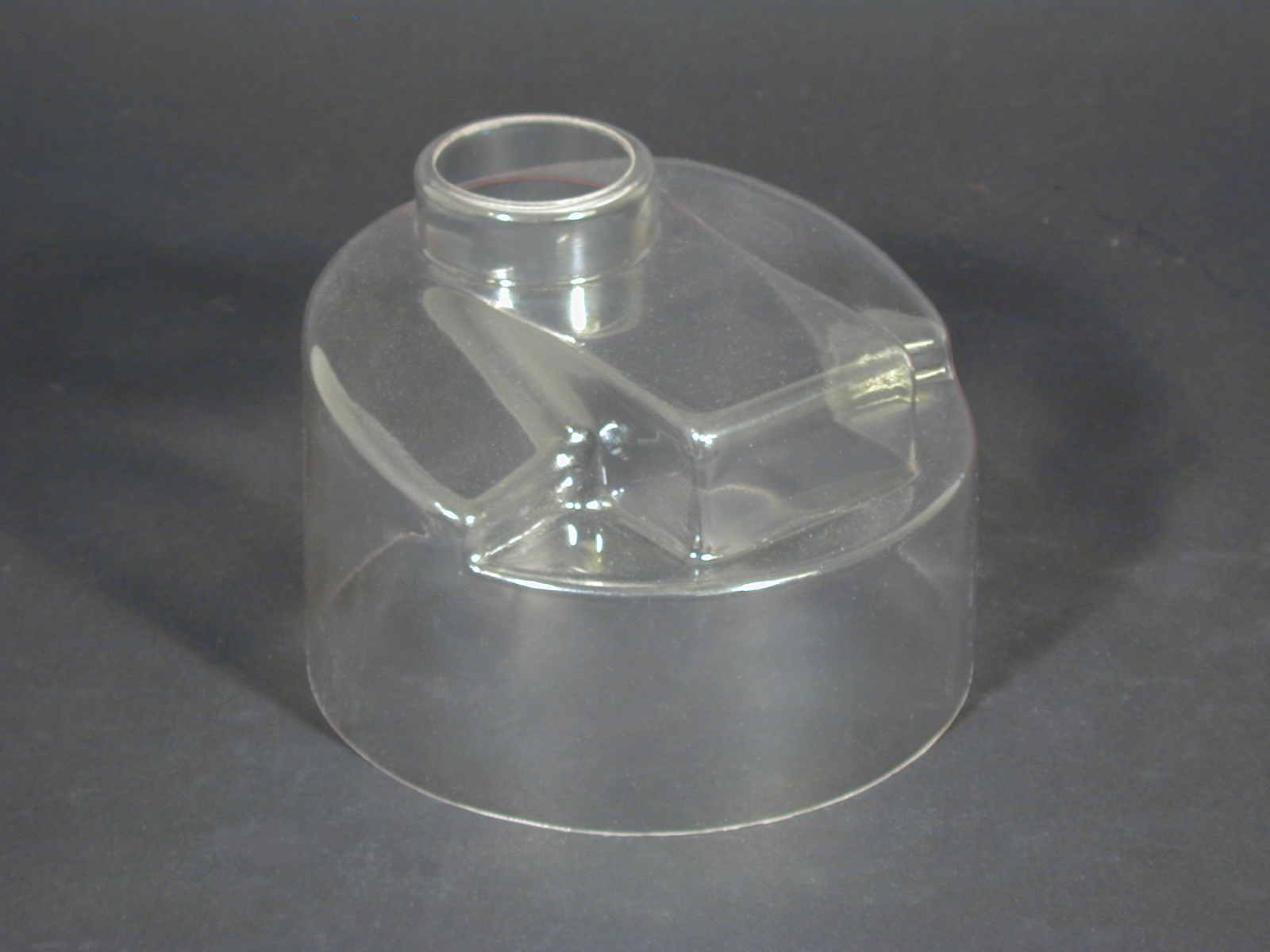

Low Pressure Injection Molded Urethane

This type of molded urethane is produced by injecting liquid urethane into a closed mold at low pressure. This technique is utilized in cases where component shape, component size, or tooling configuration would make the process of compression molding impractical. Injection molded urethane products are intricate and highly precise.

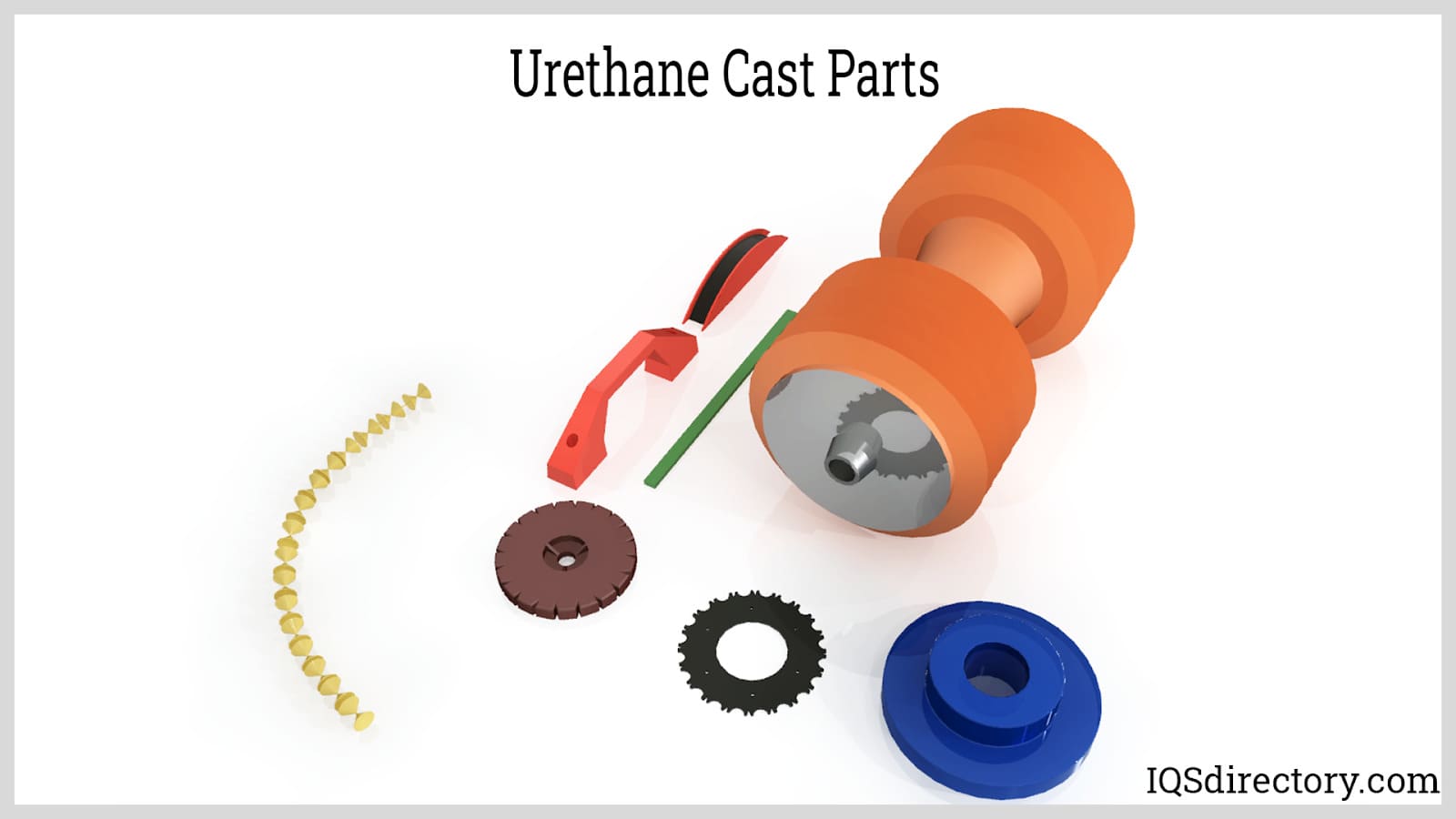

Open Cast Molded Urethane

This type of molded urethane is made by pouring liquid urethane into an open mold. The mold will then be cured in an oven or heated table. Molded urethane products produced in this way are high-performance.

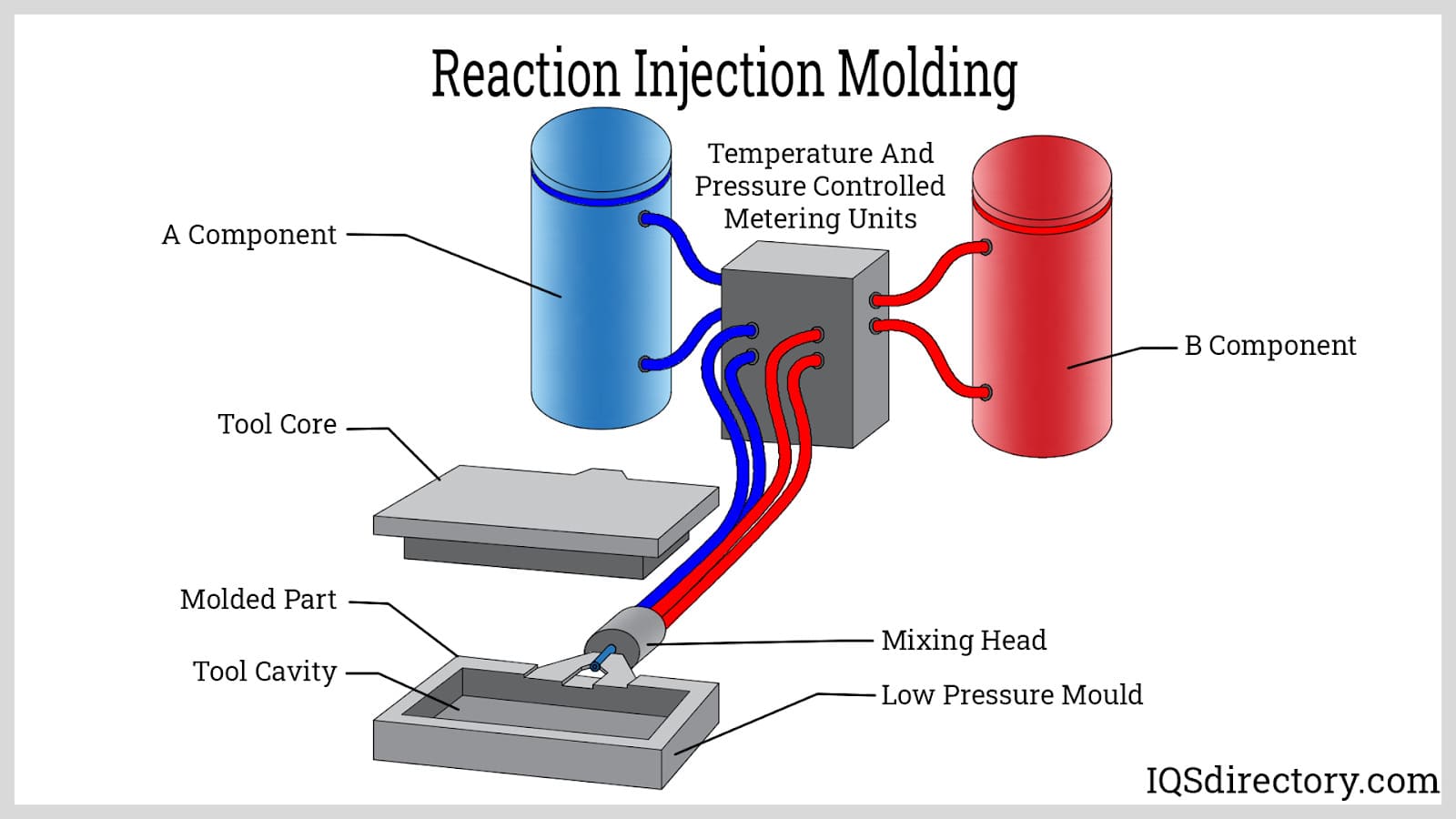

Reaction Injection Molded Urethane

Molded urethane made by this technique is made by injecting isocyanates and polyols into a closed mold. This will trigger a chemical reaction that causes the expansion of the material to form the finished product.

Applications and Benefits of Molded Urethane

Some applications and benefits of molded urethane include:

Applications of Molded Urethane

Molded urethane products can be used in the following industrial sectors:

- Building and construction

- Transportation

- Textiles

- Fiberglass

- Steel and aluminum

- Seals and wipers

- Machinery and foundry

Benefits of Molded Urethane

- Molded urethane is considerably tougher compared to plastic.

- The one-step molding process used in producing molded urethane is more economical than the process of machining blocks of plastic.

- The process of compression molding produces large and fairly intricate parts.

- Compression molding also produces molded urethane at a low cost.

- Molded urethane is available in a wide range of hardness to meet cost and performance requirements.

- Molded urethane exhibit excellent abrasion and tear resistance, which prevents the fast aging of products

- It is also resistant to chemical agents like hydraulic oil, gasoline, ozone, silicone oils and greases, and pure aliphatic hydrocarbons.

Choosing the Proper Molded Urethane Supplier

To make sure you have the most positive outcome when purchasing molded urethane from a molded urethane supplier, it is important to compare at least 4 companies using our molded urethane directory. Each molded urethane supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each molded urethane company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple molded urethane companies with the same message.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

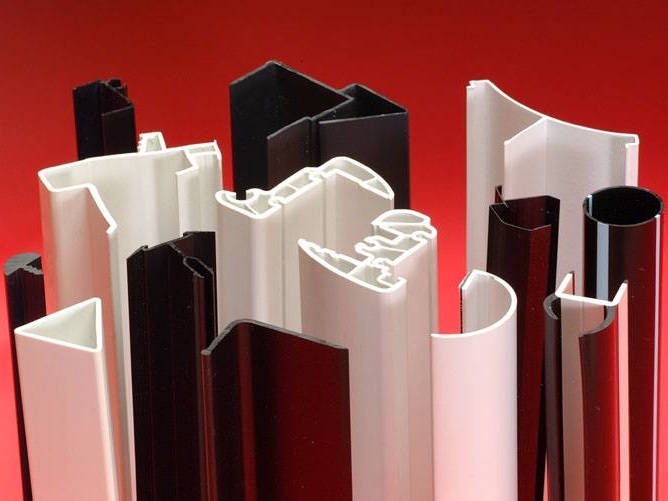

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services