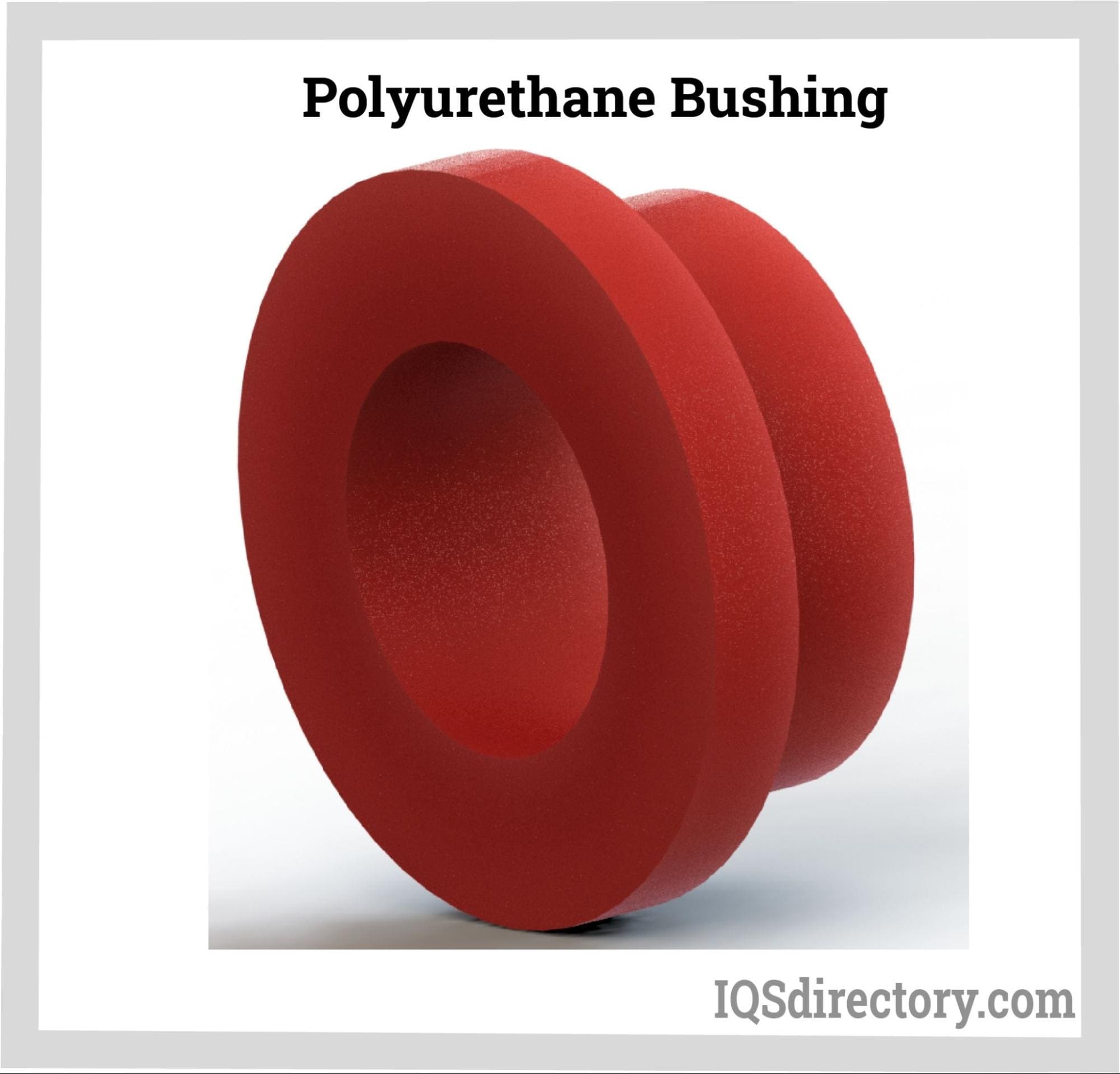

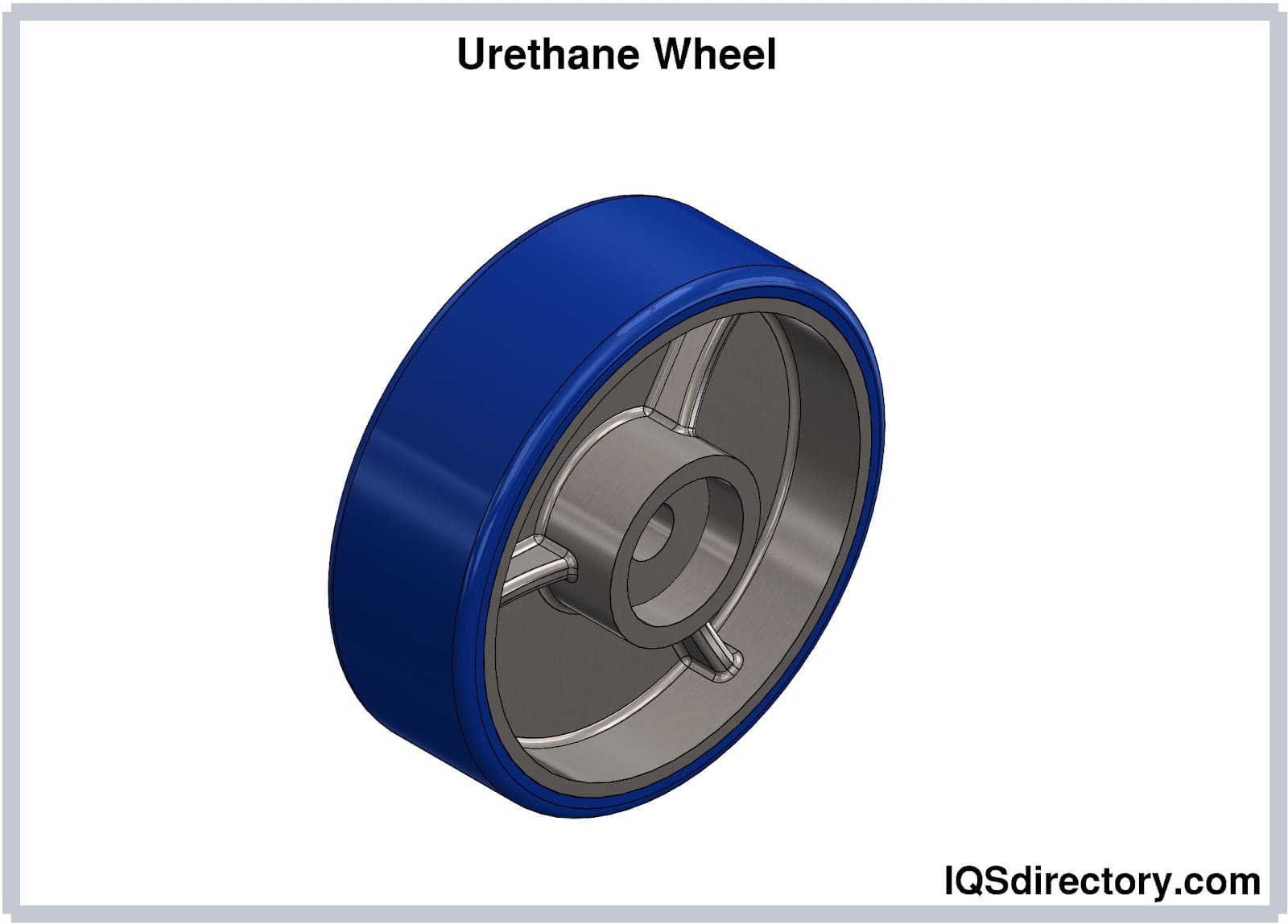

Urethane wheels combine many of the desirable qualities of plastic, rubber and metal wheels. Urethane wheels have an advantage over rubber wheels due to a higher impact resistance, broader hardness range and better colorability. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

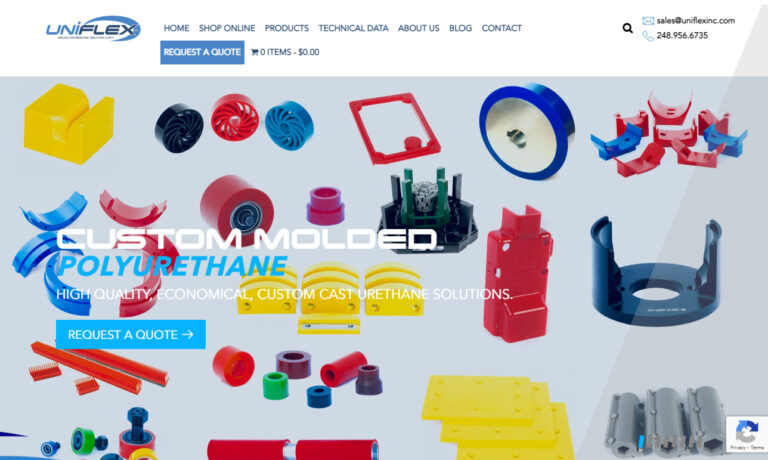

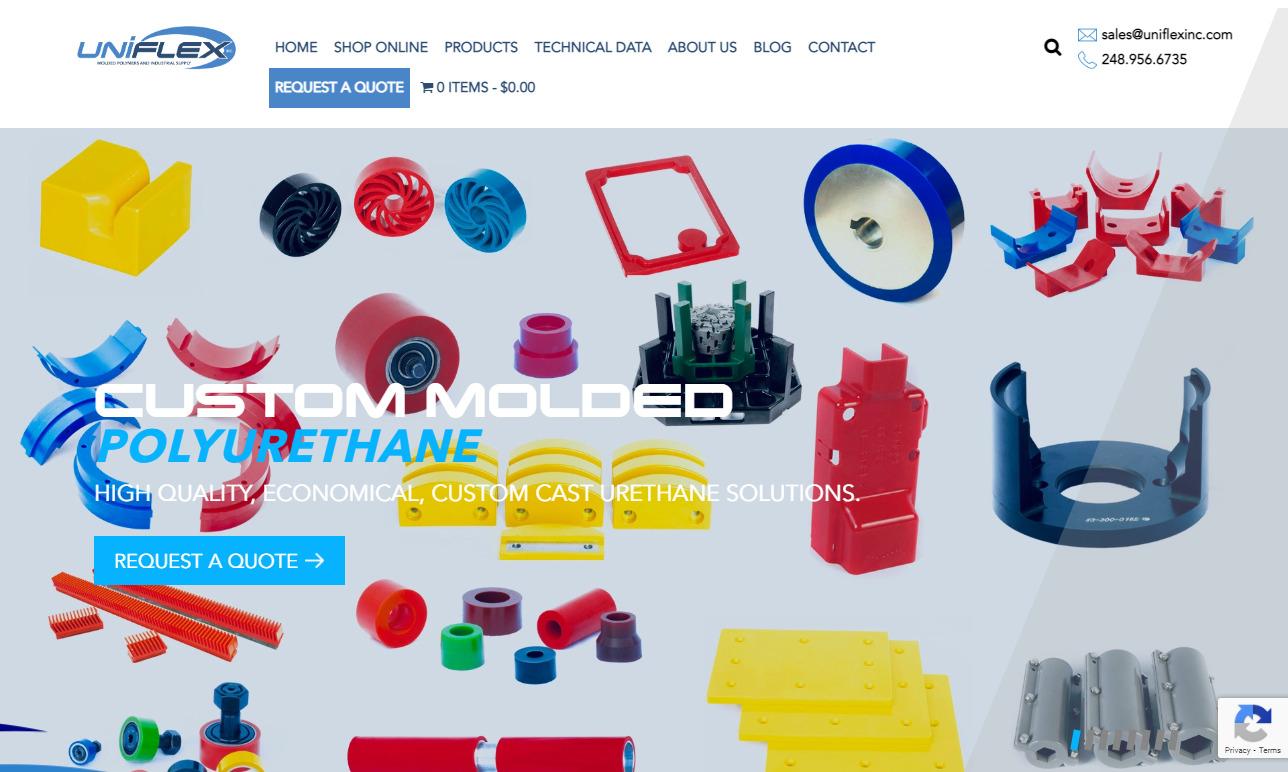

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

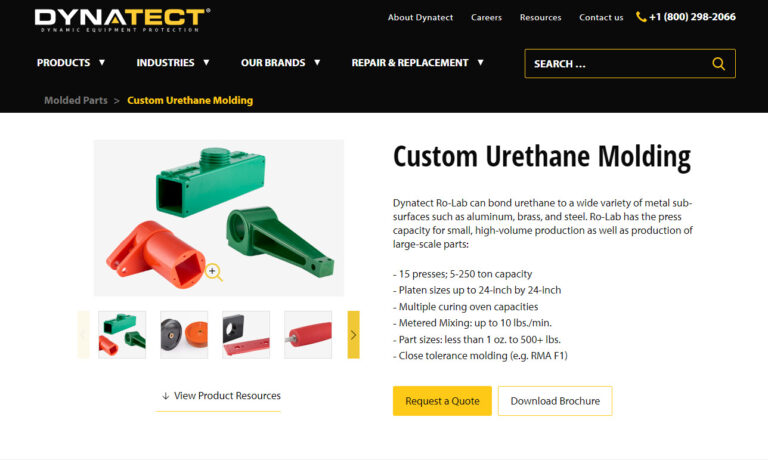

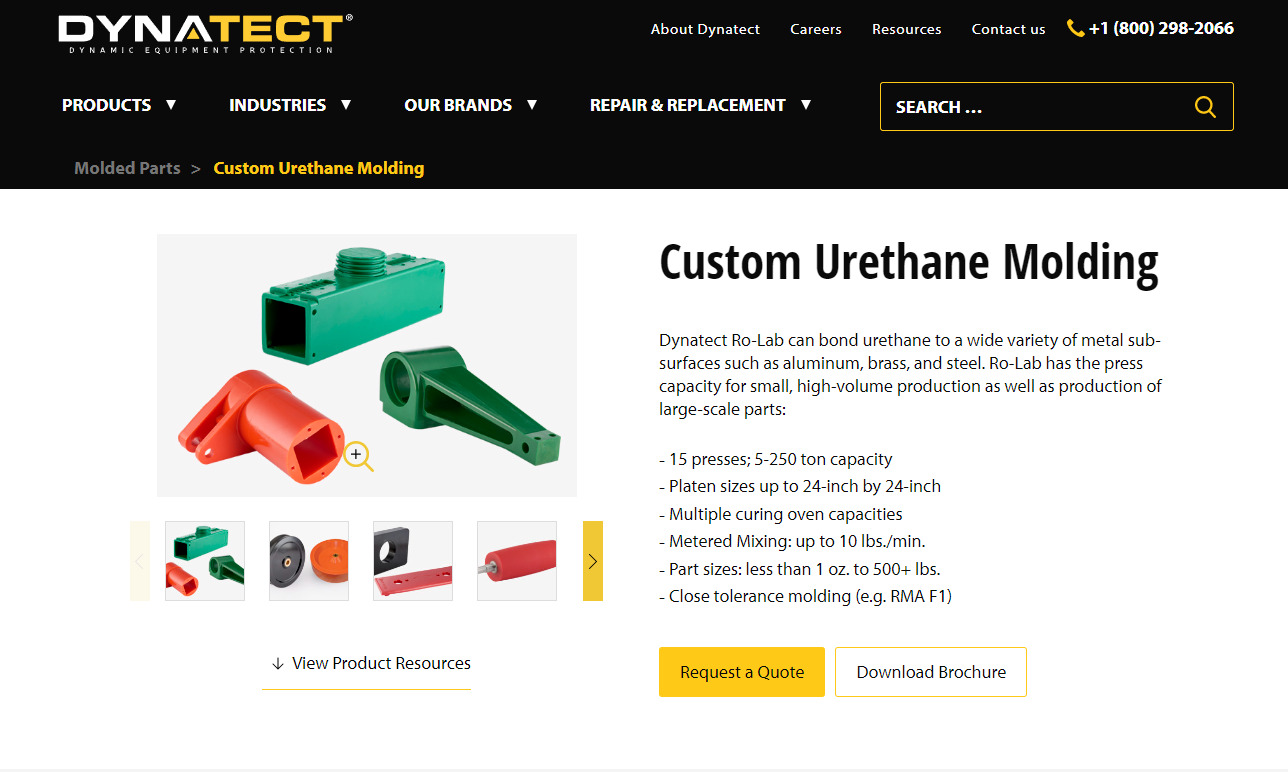

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is...

More Urethane Wheel Companies

As compared to metal wheels, urethane wheels have better noise reduction and resilience, greater abrasion, corrosion and impact resistance, more flexibility and are less costly to fabricate.

Urethane wheels function better than regular plastic wheels in many applications because they have higher impact resistance, low temperature, cold flow, radiation and abrasion resistance, better elastic memory and noise reduction capabilities, greater resilience and provide lower cost tooling.

Other unique properties to molded urethane include elastic memory, noise reduction, heat and chemical resistance, and durability. Urethane wheels can be fabricated to be sponge-soft or iron-hard in a wide range of sizes, shapes and colors.

Applications for urethane wheels include forklift drive and load wheels, rollercoaster wheels, skateboard wheels, conveyor bearings, grocery carts and carrying case wheels. These polyurethane wheel applications and more benefit industries such as material handling, industrial manufacturing, retail, transportation, athletic equipment and medical.

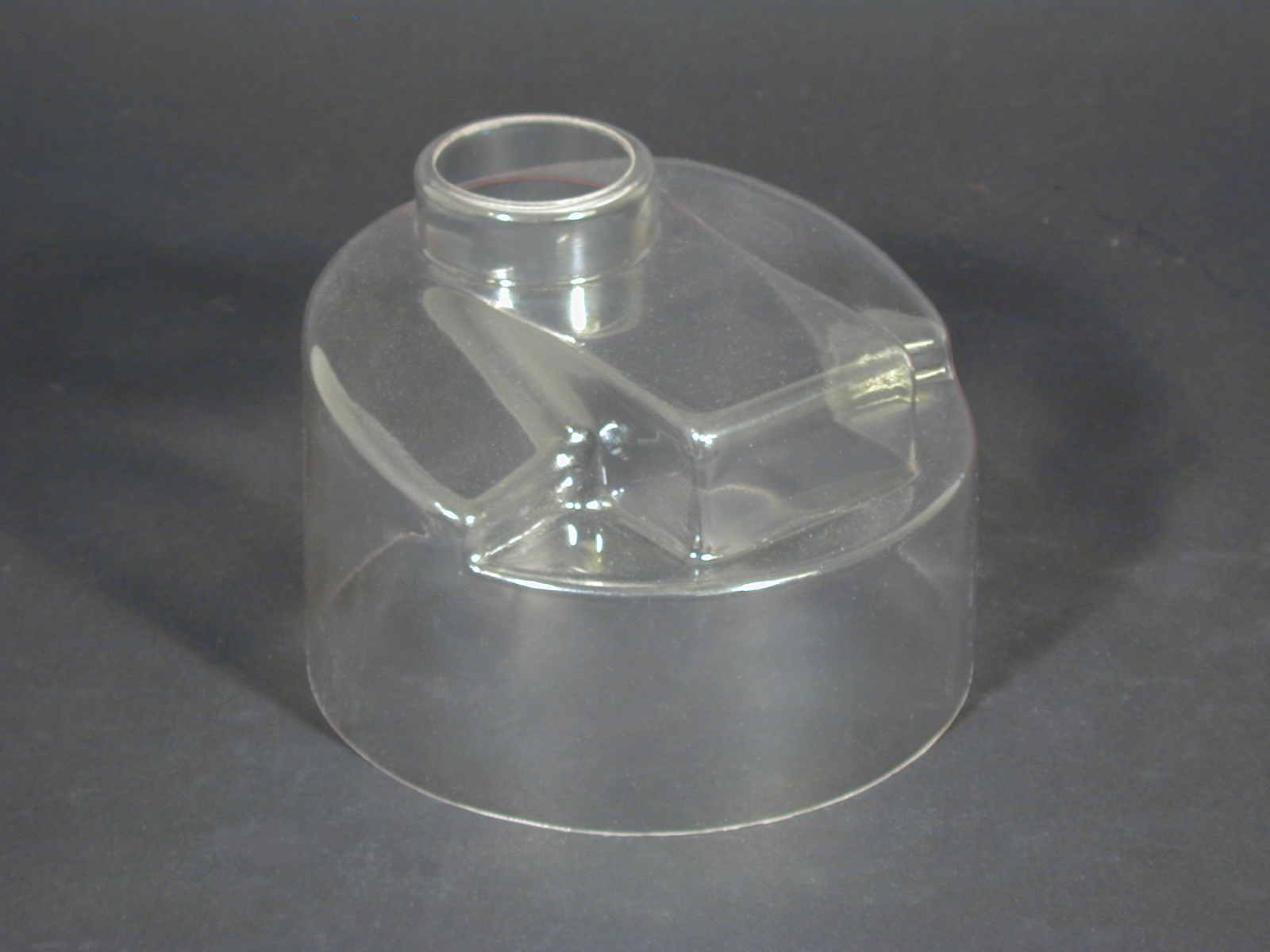

Urethane wheels are made through two main processes: liquid casting, meaning that urethane is melted down to a liquid form and then poured into a wheel-shaped mold to be cooled into a solid form; and injected molding, meaning that urethane is melted down to a liquid from and injected into a wheel-shaped mold through fill holes using a low-pressure pneumatic injection gun.

Secondary machining processes can also be used to form urethane wheels from molded urethane. Urethane wheels can consist of solid urethane or of urethane bonded to metals such as steel, aluminum and cast iron for heavy duty applications. When bonded to metals, urethane serves as the tread of the wheel and the metal serves as the core.

Different types of urethane wheels include: crowned wheels, generally used for turns in conveyor systems; engraved wheel, typically engraved with identifying marks such as parts numbers or brand names; deskew wheels, primarily used in document processing equipment; drive wheels, which offer excellent abrasion resistance for industrial machines; and compliant wheels, which are used for document processing when the documents are of varying thicknesses.

In addition, the cost of fabricating urethane wheels is economically-advantageous, and molded urethane is an FDA-approved material for clean room environments, which gives urethane wheel manufacturers a competitive edge in the medical industry as well.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services