Just a few examples of some of the applications where you may find urethane bumpers include shock absorbers for electrical components, hydraulic cylinder bumpers, industrial washing machine bumpers, bumpers for conveyor belt systems, bicycle seat shock absorbers and so many other industries and applications. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

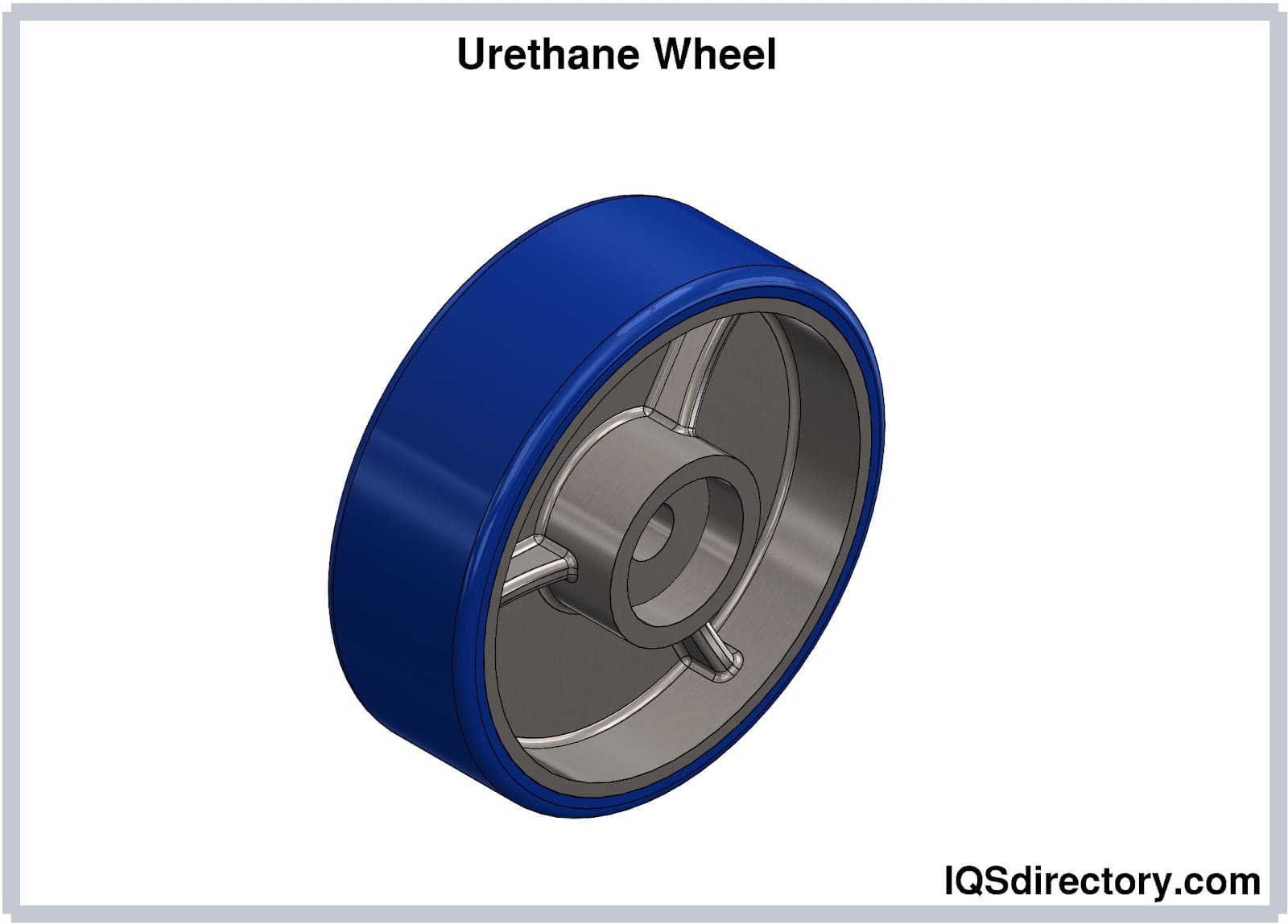

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

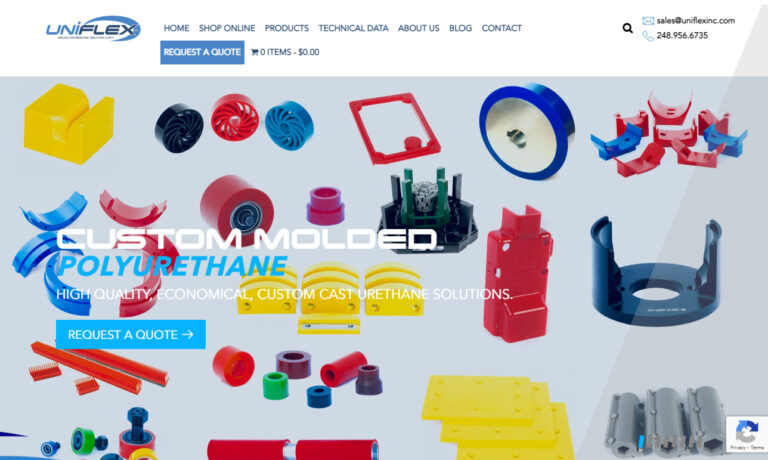

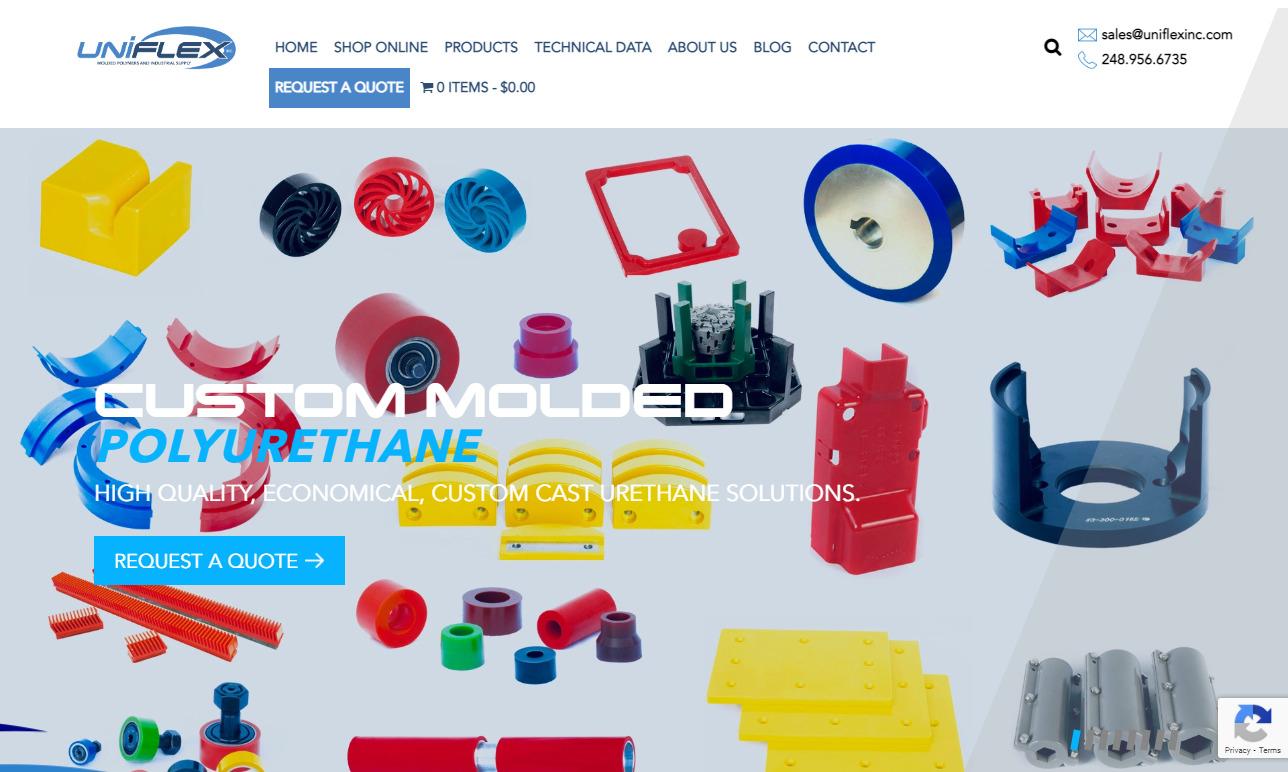

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

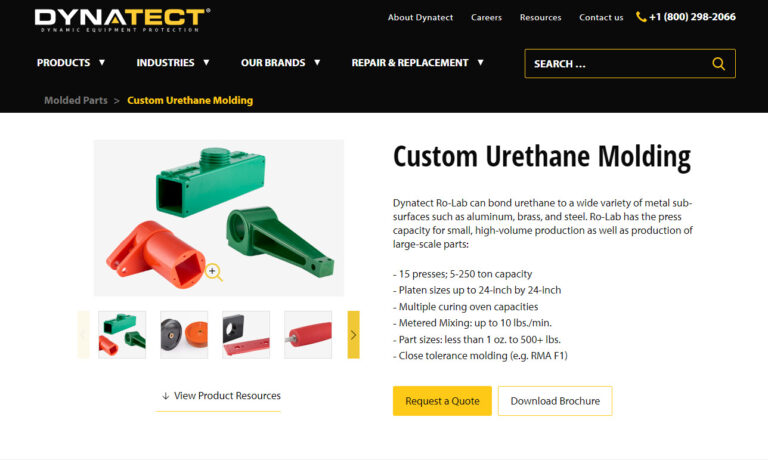

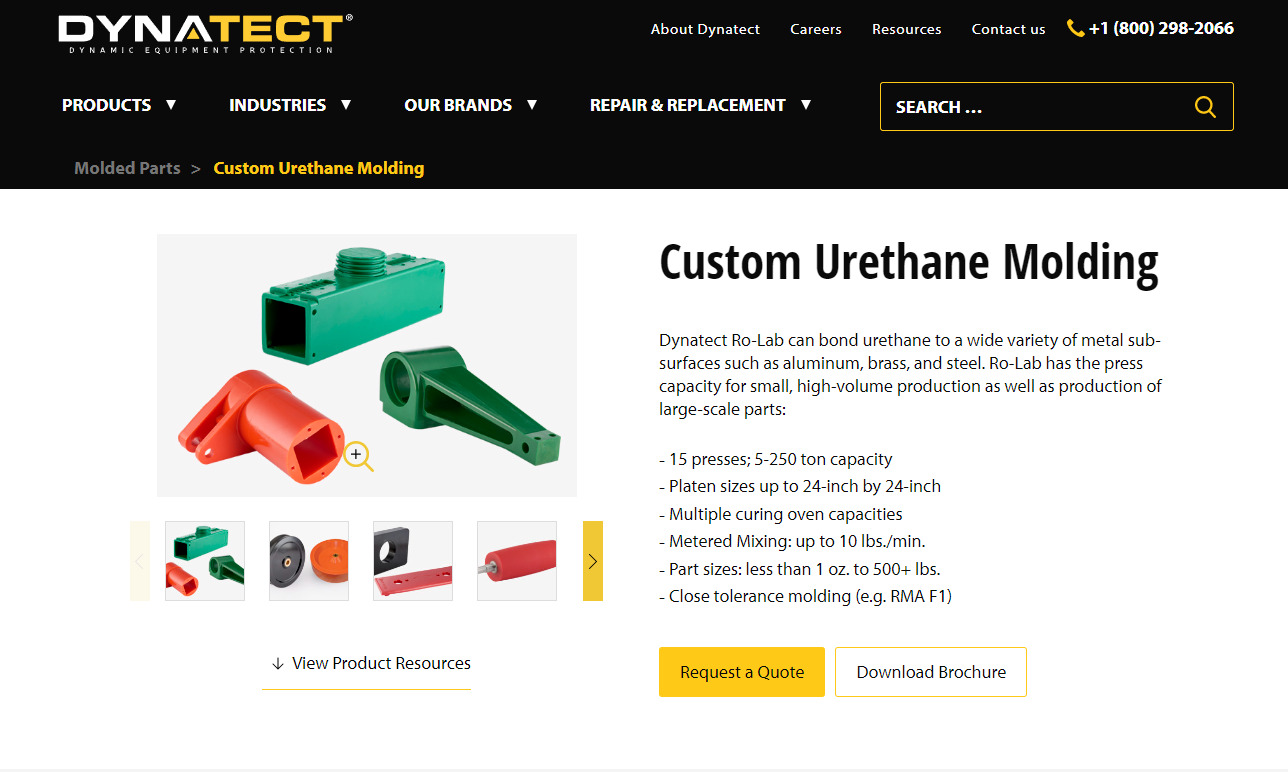

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is...

More Urethane Bumper Companies

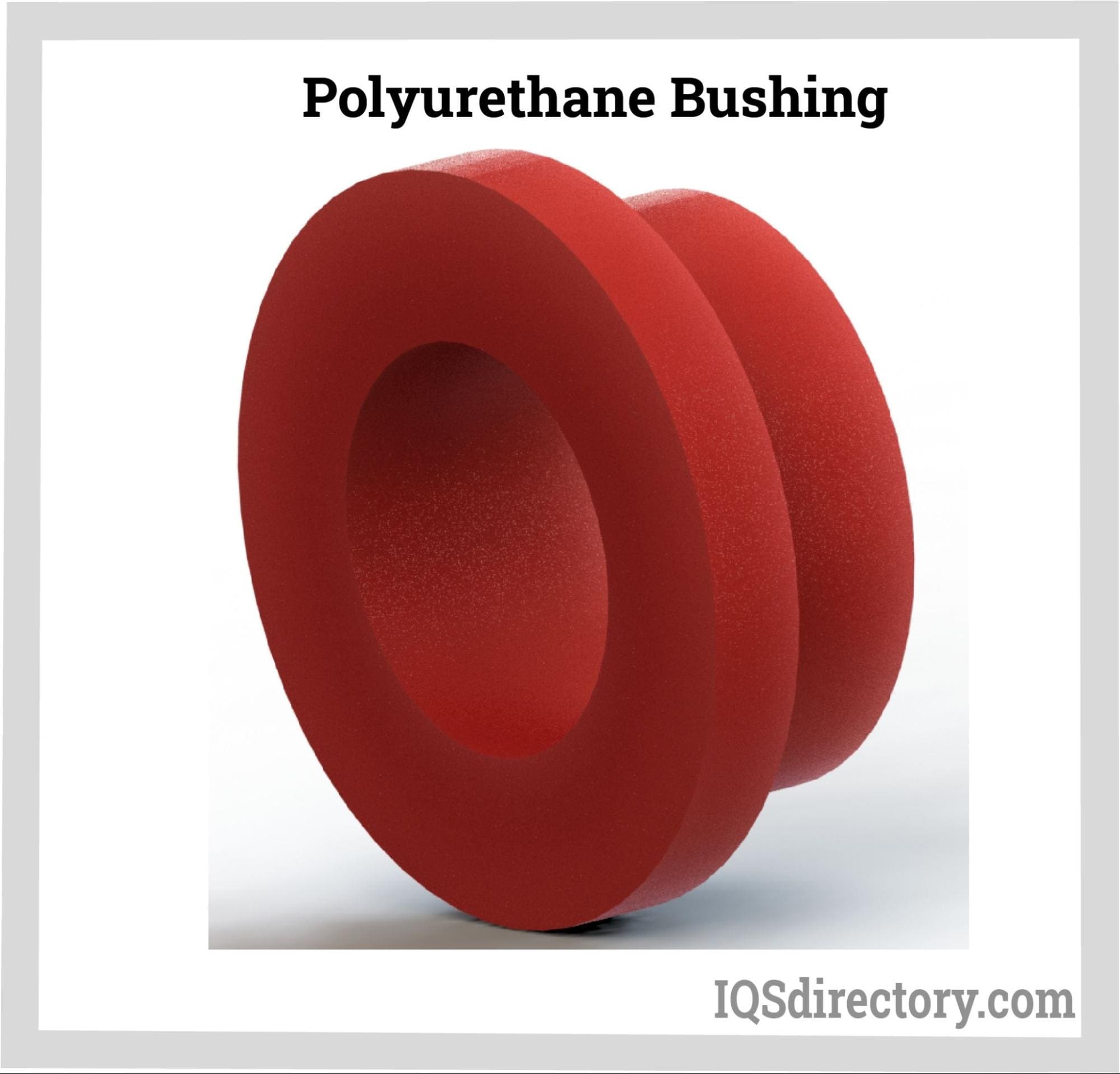

Perhaps the reason behind this is not just due to the fact that urethane offers almost countless advantages from its exceptional physical properties, but due to the fact that there are a lot of customization options when it comes to the physical properties of the material.

The hardness, chemical resistance, and other resistances can be fine tuned according to your application and the requirements that come with that application.

Urethane itself has a number of properties that make it a prime material to use for bumpers as it has both beneficial dynamic and mechanical properties in addition to being naturally resistant to chemicals, cutting, tearing and abrasion. These properties alone make it the ideal material for bumpers because, depending on what your product may be, the bumpers themselves can receive a beating from sharp edges of products, and can withstand excessive wear and tear.

In addition to being wear and tear resistant, urethane bumpers also have a high impact strength which means that they will not break if something hits them at high speed. They are also capable of being made with varying hardness which means that if you work with a fragile product, urethane bumpers will be able to cushion the product as it moves along a conveyor system.

For this reason, it is important to understand your application and what type of urethane bumper you might need for it. Just about all of the physical properties of urethane bumpers can be adjusted in order to better fit your application during the manufacturing process.

Working with an experienced urethane manufacturer is key to receiving the best possible product as they will work with you to manufacture a urethane bumper with all of your applications, requirements, and specifications in mind.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

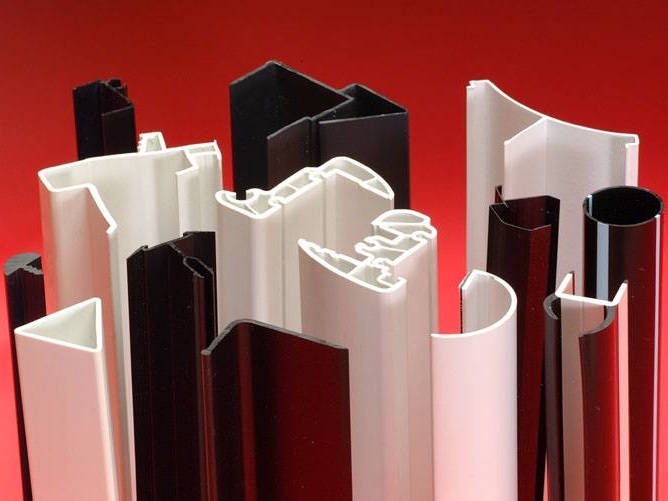

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

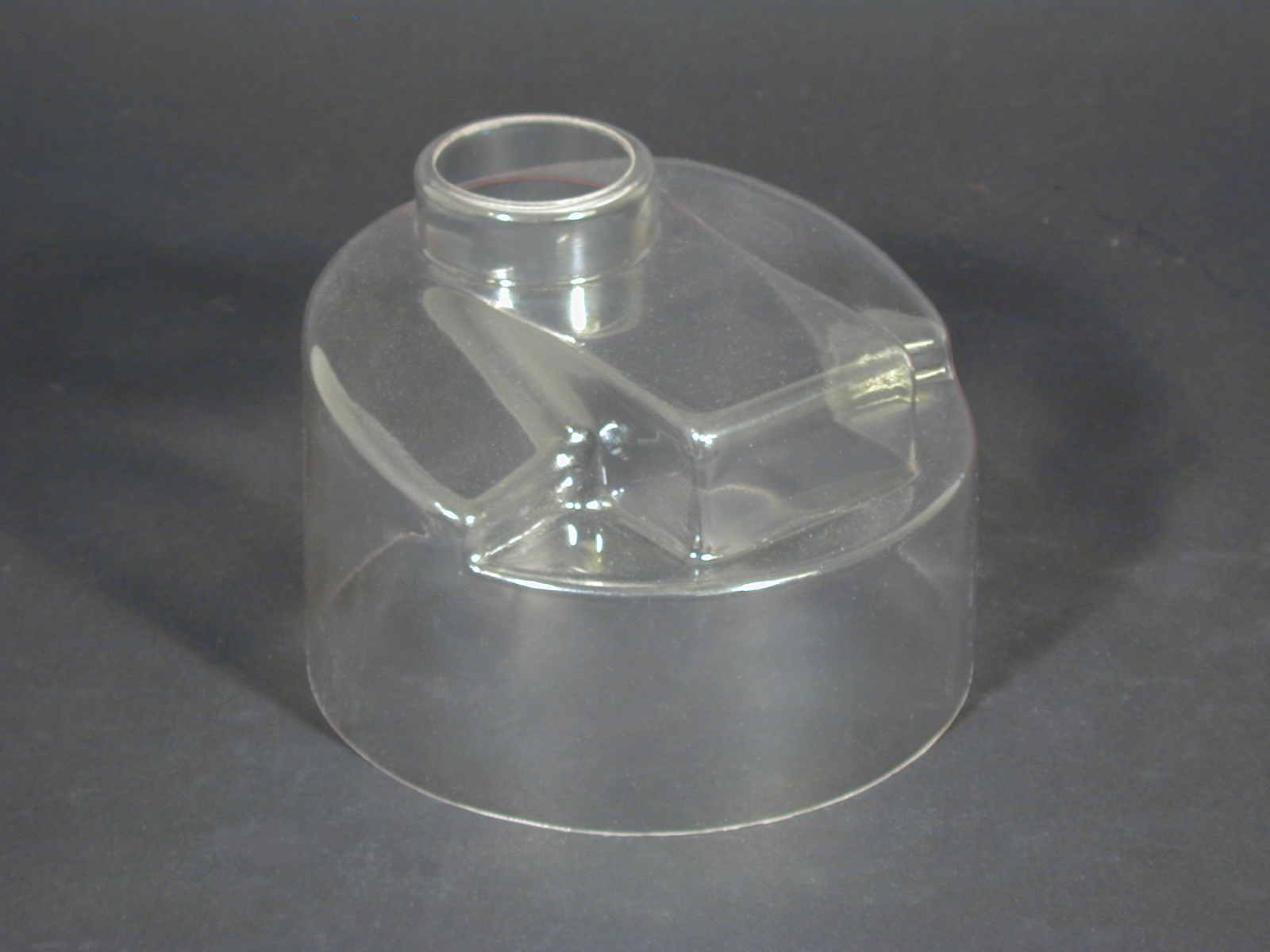

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services